Digital Transformation Solutions and Services for Aerospace & Defence Manufacturers

ATS Global has been a key driver of digital transformation in the global aerospace and defence industry for decades. We serve premiere aerospace and defence organizations cutting across OEMs, Tier-1s, Tier-2s and component suppliers. Our domain experience spans from underwater defence submarines to high-flying commercial aircraft, from complete engines to elementary casting components.

We have been instrumental in technological evolutions at major aerospace and defence installations over the past 3 decades and our rich portfolio of products, solutions and services has helped global aerospace and defence manufacturers in their Automation & IT, quality and digital transformation initiatives.

We are the prime reason behind continuous uptime of production critical applications at our customers´ global production sites, and we are proud to be associated with five of the global top-10 commercial aircraft manufacturers.

ATS is one of the world’s leading Aerospace & Defence digital transformation specialists with global delivery capabilities across a wide range of solutions

5,000+ projects in aerospace and defence

Customer portfolio of 5 of the Top-10 Commercial Aircraft manufacturers

Experience of implementing aerospace systems in accordance with AS9100 standards for QMS

What do we do?

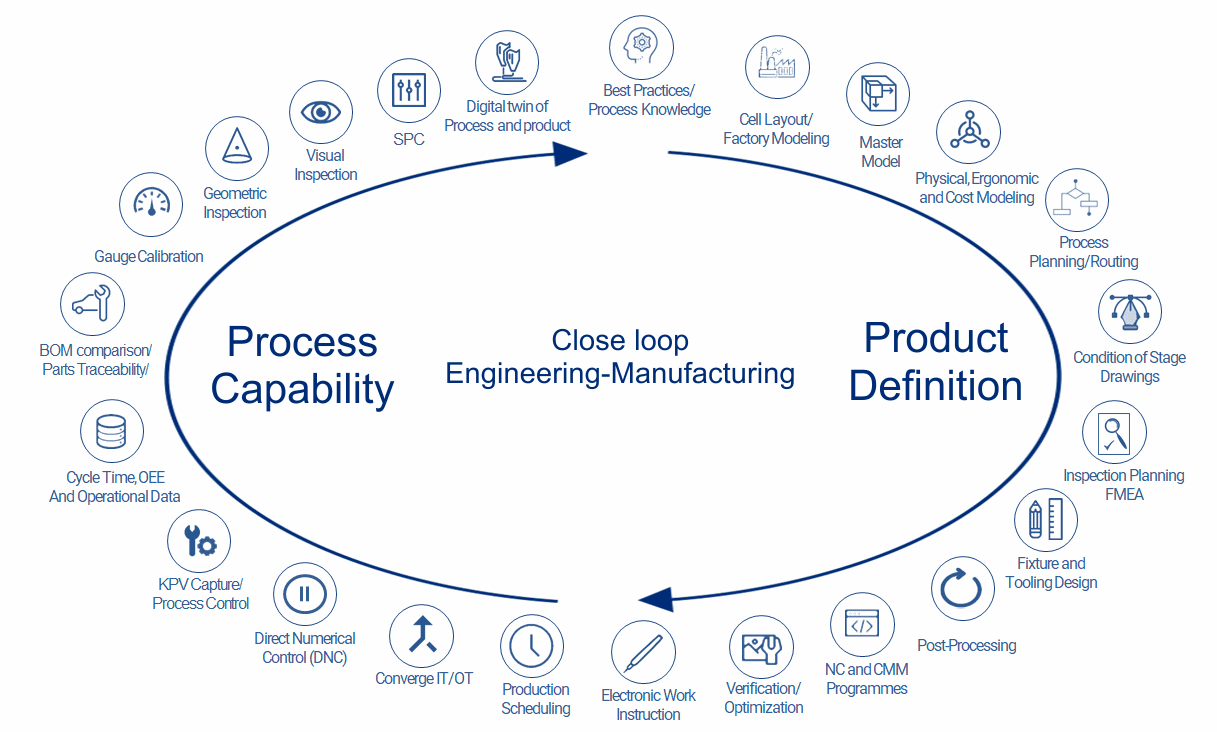

- Manufacturing Operations Management for full traceability systems

- Aerospace Quality Management solutions for Visual and dimensional analysis

- Management of shop-floor operations for repair processes

- Virtual commissioning and maintenance of a high-fidelity digital twin

- Aerospace automation solutions, consultancy and project management

- Process Planning, Assembly Engineering and Manufacturing Knowledge Management systems to enable highly repeatable operations with fewer resources requiring less training

- Aerospace MRO support and consultation

- Production planning and scheduling for aerospace and defence industry

- Capturing and utilising key process variable data from the manufacturing process to self-correct and prevent faults from progressing

- IT/OT convergence solutions for equipment connectivity and integration of Manufacturing IT systems (e.g. MES, ERP, PLM)

- Deployment of Industry 4.0 technologies, including IoT, location awareness devices and data analytics with predictive capabilities

- Andon and OEE KPI / efficiency analysis

- Consultancy for vendor management & development

How do we do it?

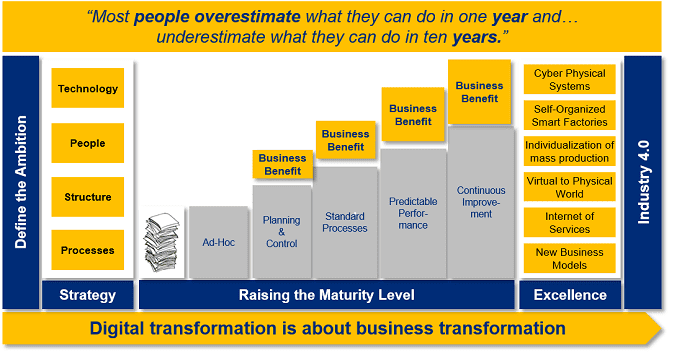

ATS enables its customers to transform their digital initiatives into roadmaps with achievable milestones and then execute them with precision. We leverage our decades of experience in the aerospace and defence industry through a combination of Training, Consultancy, Project Management, Products, Solutions, Services and 24/7 Support to realize our customers’ visions.

Our aerospace and defence offerings cover all of the processes, data, applications and technologies required to fulfil aerospace digital transformation initiatives. We provide an expert perspective on the top technology trends and options available in the market.

We are a flexible and reliable partner and utilize a range of commercial models such as On-site Support, Fixed Price Projects, Software Maintenance Agreements, Service Level Agreements (24/7) as well as Master Service Agreements.

Your Benefits as a Customer

Reduction in aerospace quality issues, leading to improved productivity and reduced costs

Faster release of product/process changes to the shop floor, improving agility

Improved flow and reduced inventory

Standardisation of processes and technologies across plants

Improved efficiency and reduction of downtime

Accelerated implementation of aerospace digital transformation strategies

Got a question about digital transformation in the Aerospace & Defence industry?

Success Stories