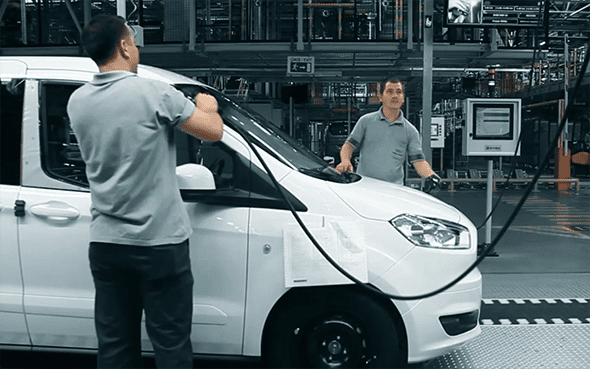

A Smart Solution for Gap and Flush Measurements in the Automotive Industry

It is essential to record gap & flush and door velocity measurements quickly and accurately, as it is critical to stay within the takt time during the final assembly verification.

ATS DoorIT is a boon to automotive manufacturers as it provides a single solution for both gap & flush and door-close velocity. It combines high-accuracy measurement devices with real-time analysis, as well as integration to your shop floor and the enterprise layer (MES/MOM/PLM).

Enabling traceability of your data across the shop floor and the assembly line, ATS DoorIT brings complete production visibility. This assures that every vehicle is leaving the plant as designed.

A Smart Digital Transformation of Your Gap & Flush and Door Closing Velocity Testing

Dimensional Body Quality

Achieving a high level of dimensional body quality requires effective measurement of gap & flush and door closing velocity. These measurements need to be accurate and the recorded data needs to be accessible and actionable. However, every manufacturing plant has different requirements and will require a tailored solution. This is where ATS DoorIT comes in.

Understanding Your Needs

Our Consultants have a wealth of experience, ranging across Automation & IT, Lean & Six Sigma, Quality Management System, and Product Lifecycle Management. It enables them to tailor a solution for your door quality requirements. After thoroughly analysing your existing system, the team will design a prioritised project to achieve it in a way that fits in with your ongoing business needs.

Implementing Your Vision

ATS will manage the complete implementation of the solution and training of your staff. This is an integral part of the project to ensure that the new business practices and processes are understood and followed to reap its full benefits.

Efficient Measurements

An easy to learn guided process means it takes an average of just 2 seconds to measure gap and flush on each section.

Track and Trace

With connectivity to the execution level enabled by ATS engineers, all measured data is traceable by vehicle identification number.

Assigning Repairs

Repair tasks are automatically assigned for all vehicles with issues and estimated repair costs are calculated.

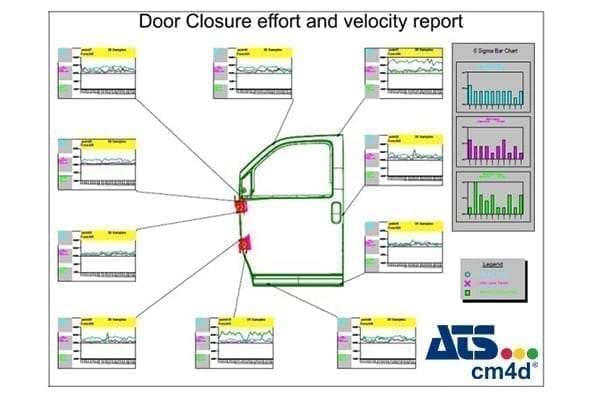

Six Sigma Support

All relevant data is delivered to process improvement teams to support Lean & Six Sigma initiatives, helping to analyse and control critical-to-quality indicators relating to body performance.

Prevent Defects Leaving the Plant

Vehicles with defects are automatically blocked from leaving the plant, making it a perfect error proofing system.

Visualise 100% of Your Production

With ATS DoorIT, manufacturers can visualize 100% of their performance compared to traditional tools where only a fraction of the door closing performance can be measured.

How ATS DoorIT Works?

Watch the video to find out how ATS DoorIT works.

Features

- Wireless Data Transmission

- Works with any door or panel

- Easy to program and use

- Robust Design

- Multiple Data outputs

- Real-time analysis

- 24/7 support available