Ford Motor Company chooses ATS Global for Quality System for Door Closure

Purpose

- Improve the visibility of the car door closure quality management

- Enhance traceability by the vehicle identification number

- Create an error-proof quality and production system

- Support lean six sigma implementation

- Optimize the repair cost

Project Scope

- Provide solution for gap and flush measurement system at the car doors

- Enhance connectivity with the execution level

- Automatic assignment of repair tasks based on faults/ errors identified

- Analyse and control critical-to-quality indicators relating to body performance

Solution Approach

- Created a simple visual guidance solution supported by complex algorithm to support gap and flush measurement

- Vehicles with low performance are automatically blocked from shipment

- All relevant data governing the lean six sigma initiatives and critical-to-quality indicators were intelligently collected relating to body performance

Systems & Tools

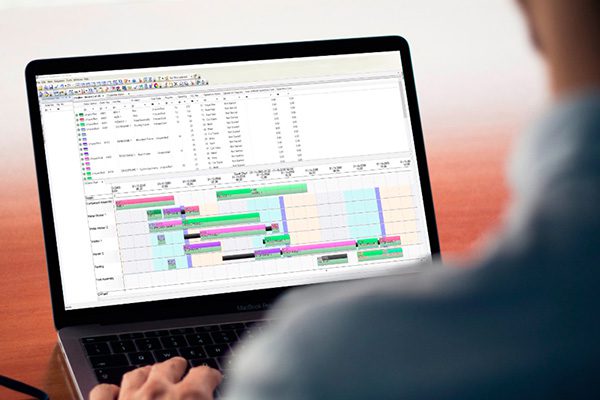

- ATS ADOS suite of products

The Results

On an average, it took just 2 seconds to measure each section

100% visualization of the door closure performance

Support in process improvement initiatives due to availability of statistical data