The Industrial IOT Platform Giving You No-Code Shop Floor to Top Floor Integration

For manufacturers who need seamless integration between departments, ATS Bus is a no-code Industrial IoT platform that provides flexibility and scalability to IT and OT systems.

ATS Bus brings true synergy from the factory floor to the top floor with all systems, software, equipment and the Cloud communicating through a single, configurable hub. Imagine what you could achieve with seamless integration across the IT/OT divide.

An IIoT Solution that Gives You the Flexibility to Manufacture Your Way

So How Does ATS Bus Bring Your

Plant Together?

Find out how this Manufacturing Service Bus connects all of your production systems increasing data security, network reliability, and resilience and decreasing the time you have to work on it.

Interested to know more about ATS Bus?

Download our brochure copy now.

Main Features

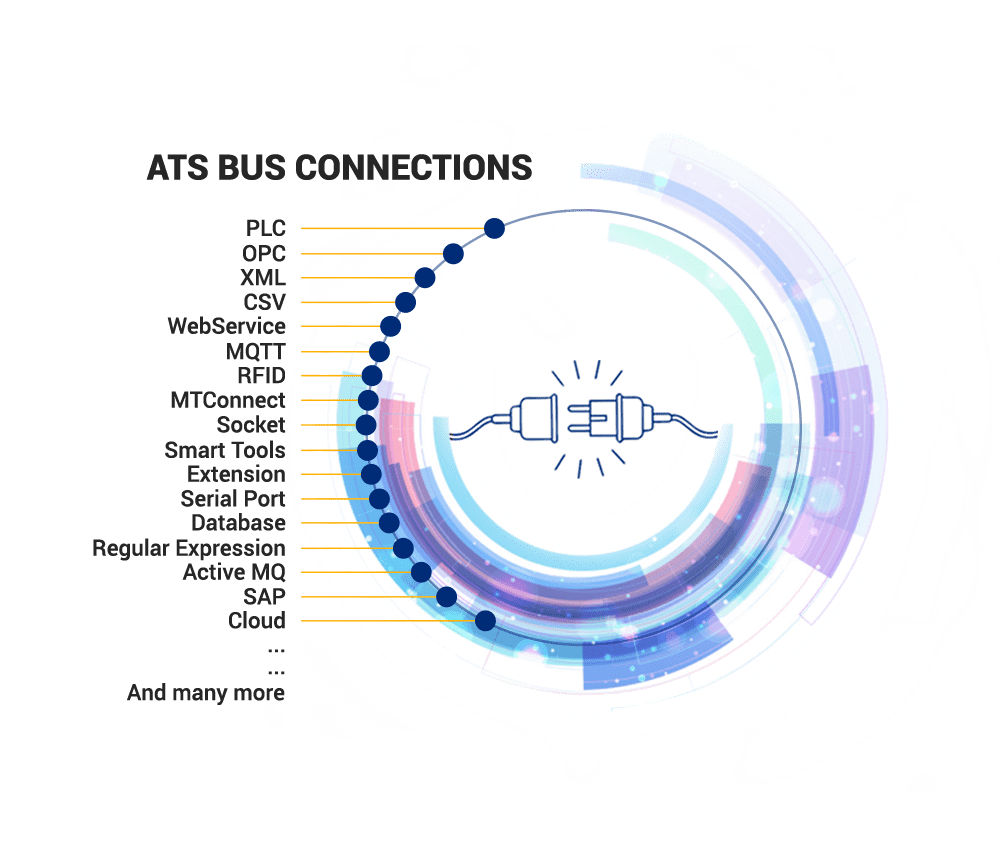

Universal Connectivity Across IT and OT

Acts as a Manufacturing Service Bus to exchange data between the separate worlds of Information Technology and Operations Technology.

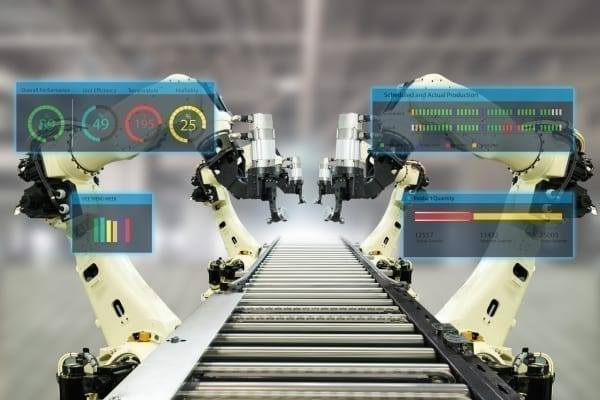

Centralised Control and Monitoring

Complete under-the-hood visualizations of your system’s behavior, clearly displayed and visualized, immediately available and up-to-date.

Edge Computing

As an IIoT solution with localised decision making it gives you reduced latency and less bandwidth usage.

Increased Data Visibility

Gain complete exposure to production data, making it easier to troubleshoot product and process issues as well as perform track and trace tasks.

Do More in 8 Hours

Save time with fewer point-to-point connections to administer as well as a single configuration portal as opposed to endless coding requirements.

Faster Industrial IoT Implementation

A standardised method of integration for all systems, equipment, devices and sensors means that the Industrial IoT can be implemented faster than you think.

Cloud Connectivity

Extract and combine data directly from anywhere across the manufacturing enterprise and then push it to the Cloud to perform big data analytics.

Improved Business Continuity Planning (BCP)

Simplified connectivity with fewer potential points of failure improves prevention of, and speeds up recovery from, potential production threats.

Accelerated New Product Introduction (NPI)

Seamless plantwide integration means that centrally managed work instructions, recipes, and robot programs, can be distributed in the shortest time possible.

What Other Features has ATS Bus Got for You?

Many-to-Many Connectivity

Publish-subscribe messaging makes data from every system accessible to any system that wants it.

Contextualised Data

Data becomes valuable information as ATS Bus adds the context of how it was collected.

Data Security

ATS Bus uses secure connections where needed and also checks the “known good” against defined schemas.

Network Resilience

Data is buffered locally and handshakes are utilised to ensure every piece of data arrives at its destination safe and sound.

Get in touch and let’s discuss your plant connectivity requirements

Success Stories