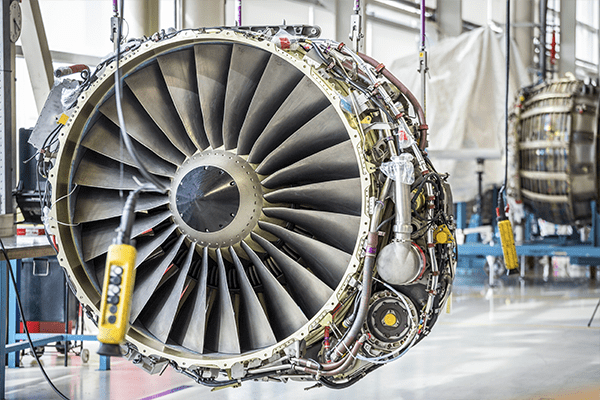

ATS Global Implements Manufacturing Intelligence System by Integrating PLM for a Leading Aerospace Engine OEM

Purpose

- Create advanced precision production processes

- Ensure process integrity by ensuring all components undergo stringent quality control procedures

Project Scope

- Process data collection direct from the machine PLCs or NC controller with in-line analysis

- ERP and PLM systems integrations

- Design and deploy the complete suite of necessary IT infrastructure – ATS Industrial PCs, ATS Resilient Factory Servers, Industrial Ethernet networking, security policies, etc.

- 24/7 support

Solution Approach

- Created a “closed loop” control system

- Process data collection direct from the machine PLCs or NC controller with in-line analysis

- Tools included- Machine monitoring, CMM (co-ordinate measurement machines), Visual inspection tools and defect cluster analysis, In-line SPC tools, Various operational dashboards

- PLM integration for one plant with gradual global roll-out

Systems & Tools

- Siemens TeamCenter PLM

The Results

ATS now support manufacturer in a total of 13 facilities in both Europe and the USA

Significant cost and operational benefits