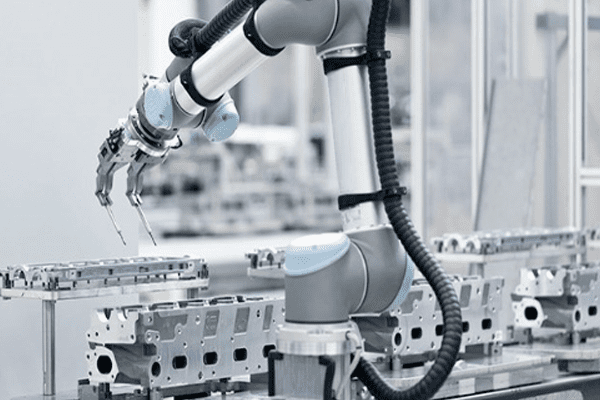

ATS Integrates Collaborative Robots in Automotive Components Manufacturer

Purpose

- Automate material handling within existing thermocouple production cell

- There are 3 existing machines in the cell – cutting machine, drilling machine and striping machine. All machines are operated by one operator

- Save man power

Project Scope

- Install 2 collaborative robots

- Design and build automatic thermocouple feeder

- Modify existing machines (electrical and mechanical) so that they can be operated by the robot

- Robots must be easy to remove (within one hour) so machines can be operated by human again if needed

- Achieve cycle time of 10 seconds

Systems & Tools

- Universal Robots (UR5 + UR10)

- Simatic S7-1200 safety PLC

The Results

Operator has to perform visual check on final products, fill input material and remove box with final products once every 10-15 minutes. So one operator can take care of more production cells

There are 3 thermocouple production cells in the plant. 1st one is already done, 2nd is in progress and 3rd one is in quotation stage