Assessing Quality in Weld Audits

Defects missed during weld audits are expensive to correct as components may be added after a frame or other substructure has been welded. Adding value to a defective structure simply means added costs to repairs or scrap.

As a supplier to an OEM, shipping non conformances on a welded subassembly means an expensive exercise in sorting, corrective action procedures and time. On top of all this, if you’re shipping in sequence to a customer, the time frame for identifying a weld issue and making repairs is short.

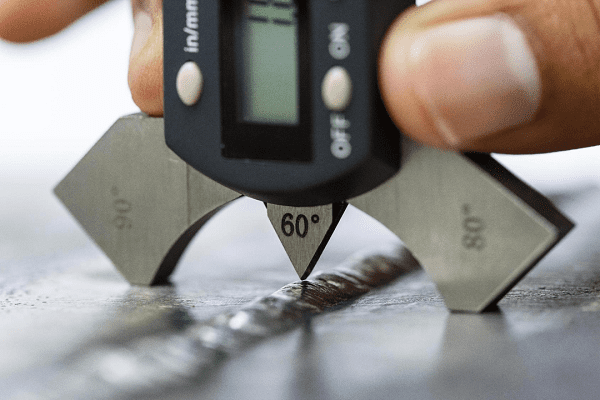

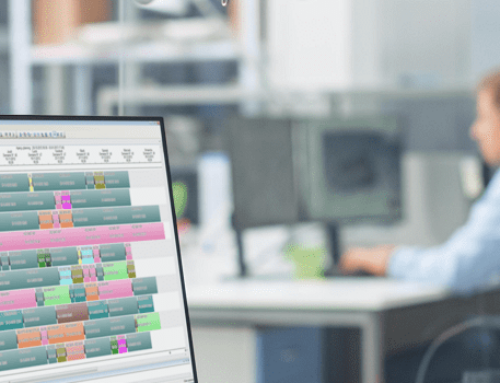

A digital quality solution can mitigate many of the problems that come with a paper-based inspection and help you to verify the critical quality aspects of your welds.