ATS Integrates Advanced Planning & Scheduling System at a Turbine Blade Manufacturer in the UK

Purpose

- Simplified, system driven, Planning & Scheduling process

- Ability to present various short-term schedule scenarios to the planning team(s)

- Obtain medium-term forecasts to support internal forecasting requirements

Project Scope

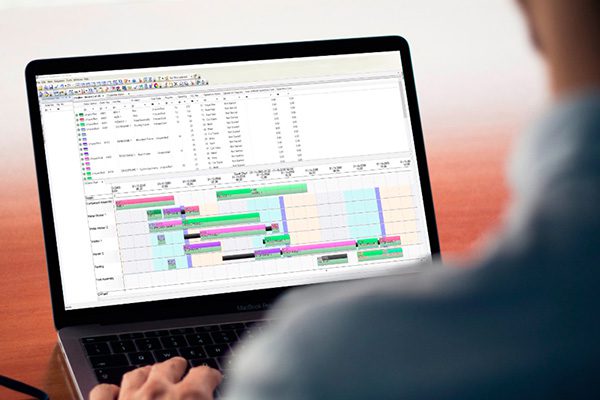

- Centralised planning/scheduling system covering:

- 100+ Machine Resources

- Operator Shift Constraints

- 5 Quarter Planning

- 300+ Sales Orders

- 15,000+ Operations

Solution Approach

- Requirements capture and high level system design via on premise consultancy

- System development/configuration, including data cleansing activities

- Deployment in parallel to existing system for data/algorithm validation

- Go-Live

Systems & Tools

- SIMATIC IT Preactor

The Results

25% reduction in customer complaints relating to deliveries

>5% yield improvement through optimised scheduling

10% increase in on-time deliveries

Improved Forecasting Ability

Enables scenario planning