13 MARCH | 3 MIN READ

What is the difference between a Six Sigma, Lean, Kaizen or Just Do It Project and when should we use it?

It is important to note that Quality Improvement is not merely a series of discrete improvement efforts but rather is part of an organisation’s culture. It’s what the most invincible companies get right.

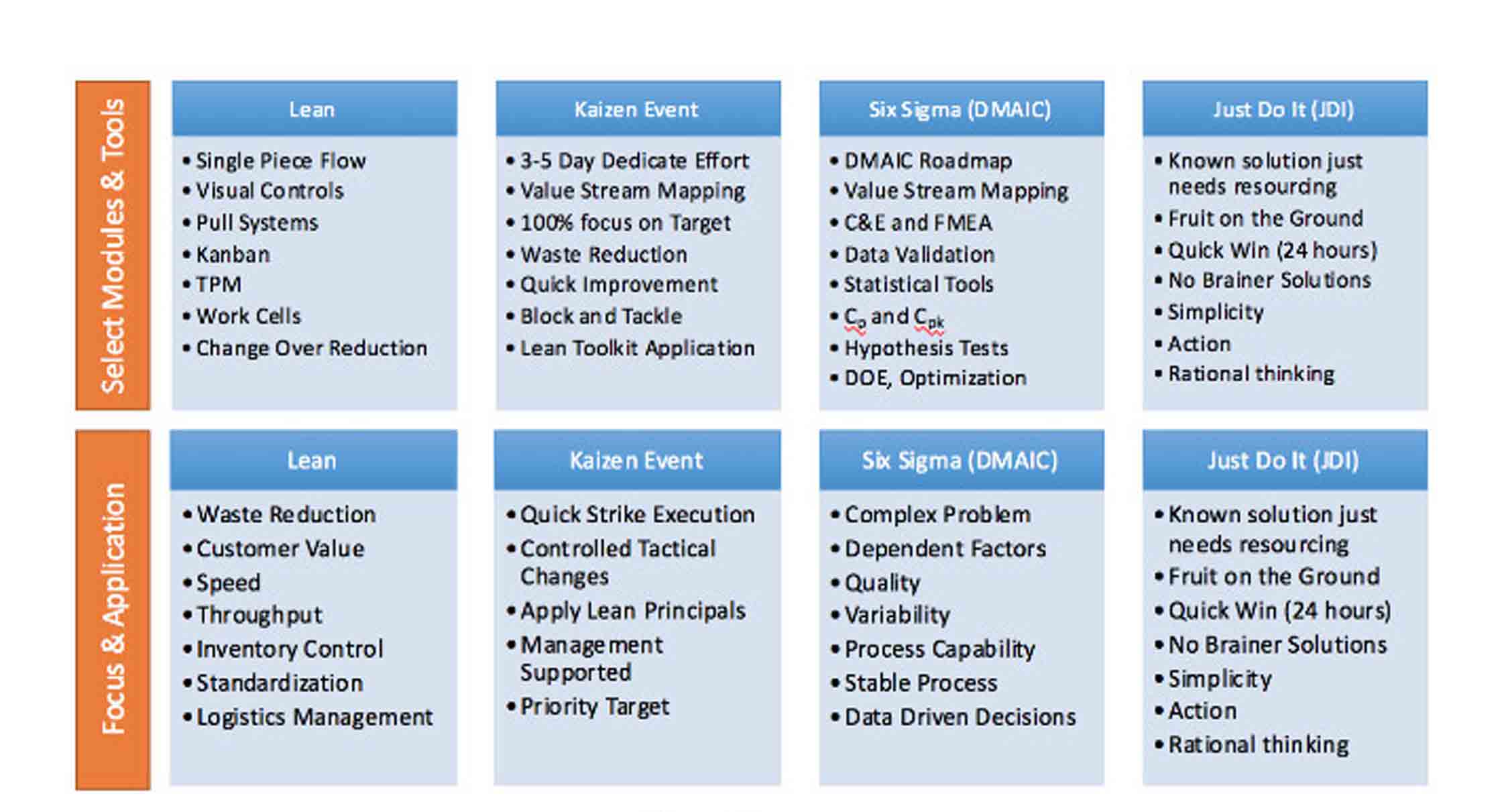

Before embarking on a project to change business process, it is worth understanding the methodologies at your disposal.

Six Sigma, Lean, Kaizen or Just Do It all (JDI), focus on improving processes and require participation from all employees involved in the to achieve maximum effectiveness.

BLOG POST

People, Process, Technology: How ‘The Golden Triangle’ Drives Digital Transformation

Read More →

BLOG POST

PPT Part 2: ‘People’ The Cornerstone of successful organisational transformation

Read More →

BLOG POST

PPT Part 3: Unleashing the Power of 'Process' in Manufacturing

Read More →

They all rely on data to understand the problem and whether changes result in improvement. Moreover, the methods all use the same tools and often combine approaches. Confusing right?

Over the years, the terms for the methodologies have lost their identity and have become diluted. These words are being used interchangeably without knowing the true meaning or use of these words. People always say they are using Lean, I don’t need KAIZEN™ or Six Sigma or vice versa.

Next, let's agree that no one can fix all your problems—we wish it was that simple. It is worth noting that although these tools add to your quality improvement arsenal, without committed leadership providing a clear focus on what the business needs to be better, the value that these sorts of initiatives can uncover if done right, can never be realised by the organisation. This would be a waste of time.

What many people fail to realise is that each concept/tool is used to solve specialised problems as opposed to the answer to every problem. Just because you have the tool doesn’t mean you should use it. No tool should be picked up or used until one can properly answer the question, “What problem are we trying to solve?”

So, we want to quickly explain some of the easiest-to-understand points associated with the various tools and methodologies that differentiate the approach—and we hope this helps with your learning.

When to use

Six Sigma:

- If the issue has been looming for a while this is recommended for complex problems where root cause analysis and advanced problem-solving methodologies are necessary.

- Best suited for projects requiring a structured approach to reduce variation and defects, ideal for critical processes demanding consistent quality.

- Utilise when aiming for significant process improvements through statistical analysis and data-driven decision-making from connecting the dots.

Lean:

- Ideal for projects focused on eliminating waste and optimising processes to improve efficiency and reduce lead times.

- Use when aiming to streamline operations and enhance overall productivity and faster, by identifying and eliminating non-value-added activities.

- Recommended for organisations seeking to foster a culture of continuous improvement and empower employees to identify and address inefficiencies.

Kaizen Event:

- Suited for projects requiring rapid problem-solving and immediate implementation of small, incremental improvements and apply lean methods in a quick-fire approach.

- Utilise when targeting specific process areas for quick enhancements, such as reducing setup times or improving workflow layout.

- Recommended for teams seeking to engage frontline employees in problem-solving and promote teamwork and collaboration.

JDI (Just Do It):

- Best for addressing 24hr simple problems or opportunities for improvement that do not require extensive analysis or planning.

- Use when immediate action is needed to resolve minor issues or implement straightforward solutions that is obvious to everyone and simply needs resourcing.

- Recommended for situations where quick wins are essential, and formal project methodologies may be overly bureaucratic.

We hope this gives more transparency in your quality projects.