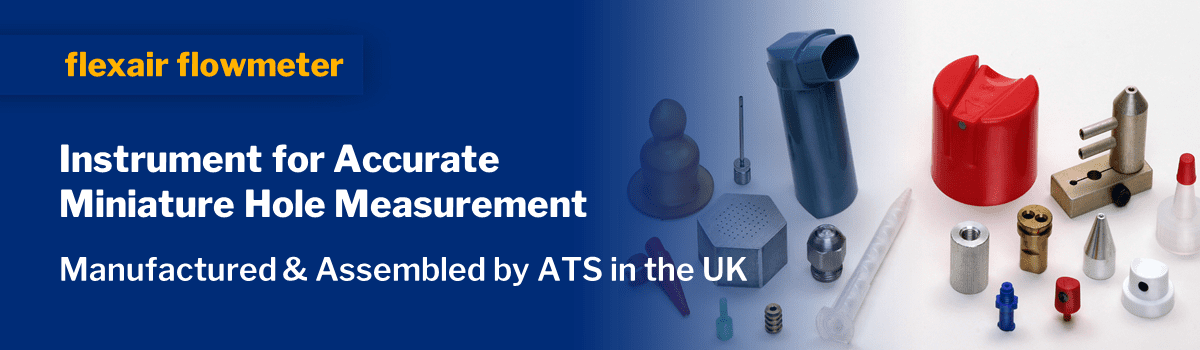

From inhalers and baby teats to fuel injectors and spray nozzles. This air/electronic instrument makes product quality tests quickly and accurately and is ideal for automated production environments as well as clean rooms and laboratories where measuring holes down to 0.002” is an essential part of a daily process.

Who is Using FlexAir Flowmeter?

Some of the biggest users of the Flexair Flowmeters are from within the life science, medical device and plastic moulding industries. The measurement of miniature holes in soft materials is extremely challenging, particularly in a high volume manufacturing environment.

Further important users are manufacturers of carburettors of small off road engines such as chainsaw, brush cutters, blowers. FlexAir Flowmeters are essential equipment of their quality inspection department.

How FlexAir Flowmeter Works?

The low pressure airflow is the key.

Using low pressure airflow has proven to be a faster, cleaner and more accurate means of measurement.

Success Story: Small Orifice Measurements in Baby Teats

From a manual visual test to search for blockages to an automatic flow testing system that is placed in line and can perform a 100% test which then sends a signal to a PLC controller to either accept or reject the components.

Further FlexAir columns replaced the manual checks, this allows SPC data to be sent directly to a reporting software, where real-time data is assessed.

A Quick Overview

Fast, efficient and accurate means of measuring small holes using low-pressure air

Built-in air filtration and regulation thus providing a plug and play instrument

Aluminium enclosure protected for shop-floor use

RS232 Output for data collection

PLC control output

The Features and Benefits of the FlexAir Electronic Flowmeters

Small Hole Inspection

Hole diameters of 0.157” (4mm) or smaller are very difficult if not impossible to inspect with mechanical gauges or non-contact inspection equipment. Flexair is designed to quickly measure holes “comparatively” down to 0.002” (0.05mm).

Air / Electronic System

This instrument combines the speed, accuracy and versatility of electronics with all of the performance attributed to pneumatics.

Comparative Measurement

Flexair performs very quick and extremely accurate comparative measurement. Absolute measurement can also be obtained by using the RS232 output for special applications.

Low Pressure Output

Low 138mb output pressure allows inspection of soft or flexible components without distortion. Minimised shop air consumption. Dramatically improves inspection throughput. Minimises set-up time for component changes.

Compact Size

Dimensions:

464mm H x 68mm W x 200mm D

Minimum space required to position on work benches or to be installed in automated in-process inspection.

Tri-Coloured Column

Easy to see status changes:

GREEN = Acceptable Range

AMBER = Approach Limits

RED = Reject

Digital Display

Clear and easy to read characters. Displays Menu Functions including Calibration. Instructions.

Membrane Buttons

Makes setup quick and accurate. Provides durability in shopfloor environment.

Tamper-proof Design

No knobs or switches to be changed or adjusted during production cycle.

Built-in Integrated Filter & Regulator

Plug and Play solution with accurate air pressure adjustments.

RS232 Output

Switchable between single output by pressing the red button on the front or continuous data-send.

I/O Control Ports

Output a relay electrical signal for PLC control or connection to footswitch.