Automotive Manufacturer can Expect the Unexpected with APS solution

Purpose

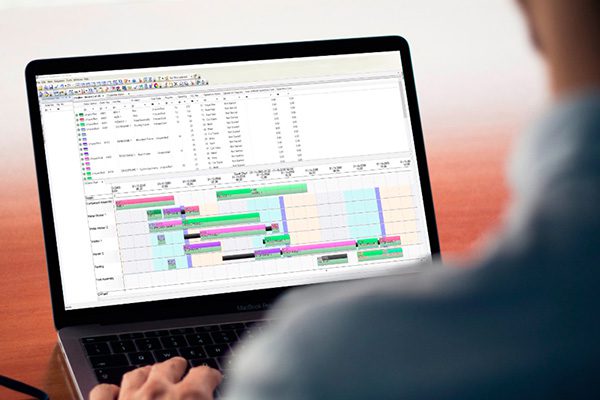

- Replace homemade and difficult-to-maintain

- spreadsheets with Preactor software Quickly compare multiple scenarios, such as the shortest change time or the most reliable life cycle.

- Standard out-of-the-box products and features.

- Able to respond quickly to customer needs. For example, if there is an urgent order, you can anticipate the impact on the current production schedule and respond.

- Establish a reliable connection between ERP and Preactor and implement interface standardization.

Project Scope

- Revision of Functional Design Specification (FDS) and Technical Design Specification (TDS).

- Deployment and joint debugging of Preactor and ATS Bus.

- Customer training

- 8×5 technical support

- Project management

Solution Approach

- Building a Prince2 project with multiple agile iterations

- Weekly consultations with project managers, stakeholders and IT department

Systems & Tools

- ATS Bus, Siemens Opcenter APS, TFS, Prince2 combined with agile methods

The Results

The new and efficient APS system allows planners to easily create and publish production plans.