09 OCTOBER | 3 MIN READ

Next generation Digital Thread: The Model-Based Enterprise Part 2

In the last article in this series, we kicked off with the definition of a Model-Based Enterprise (MBE), introduced the Maturity Index Matrix and how a company can assess itself as, and ease transition to the model. Now will explore the importance of Product Lifecycle Management (PLM).

Modernise the way you think about Product Lifecycle

BLOG POST

Understanding the Different Model-Based Approaches: MBSE, MBD, and MBE

Read More →

BLOG POST

Next generation Digital Thread: The Model-Based Enterprise Part 1...

Read More →

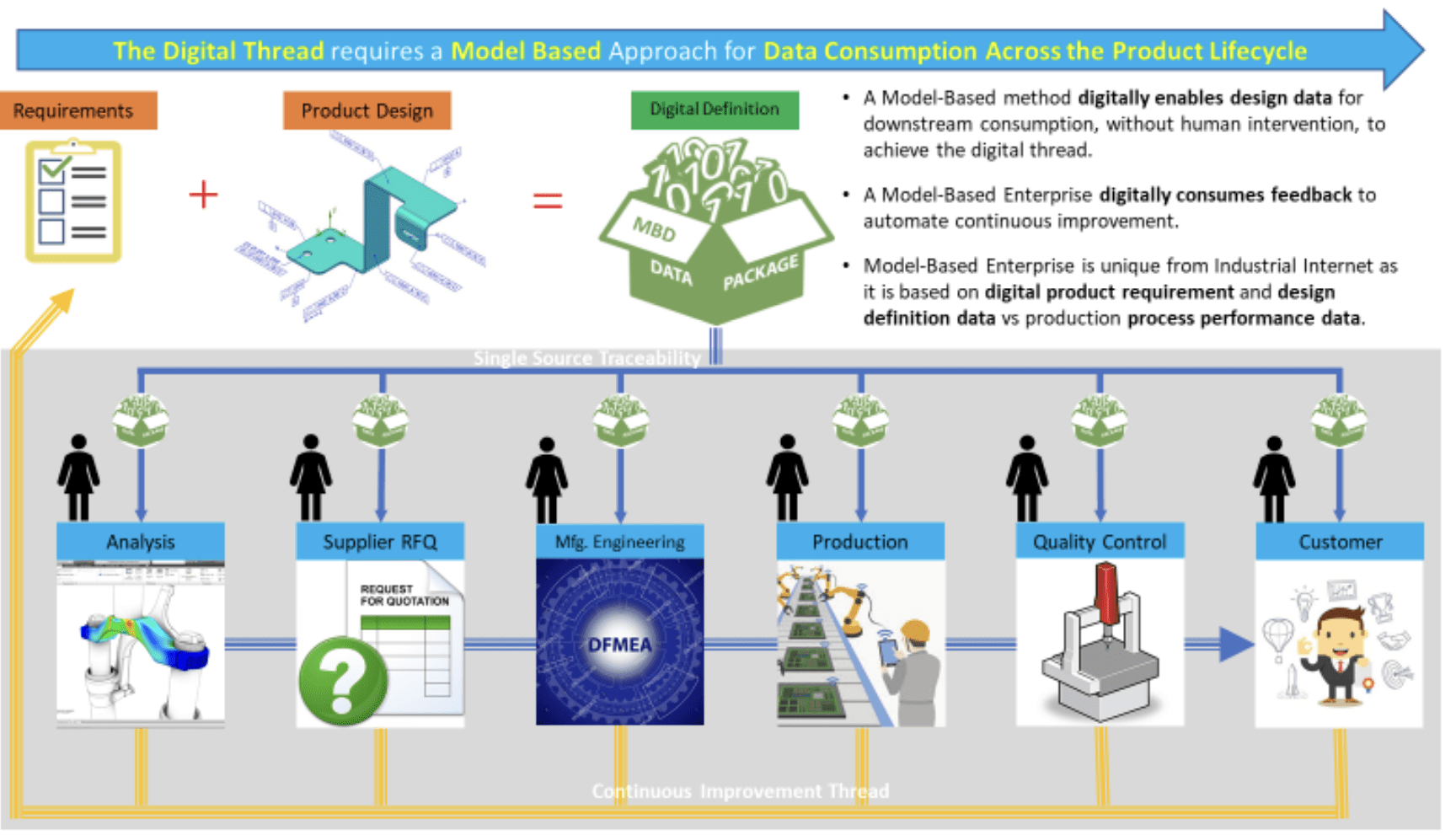

The ultimate vision for MBE is for every function to leverage the product model across the entire product lifecycle (see graphic). However, this vision will take time to realise. By planning for it now, your company can start experiencing some of the early benefits, but it can be tricky figuring out how to get started.

The Illustration shows the three elements of a complete model-based definition. (Image courtesy of www.tech-clarity.com).

Bringing it all together

When realising the vision of MBE, we refer to this connectivity as the Digital Thread and a Model-Based Enterprise. As an enterprise makes these data connections, they become a part of MBSE to understand, control, and predict the processes that define the business.

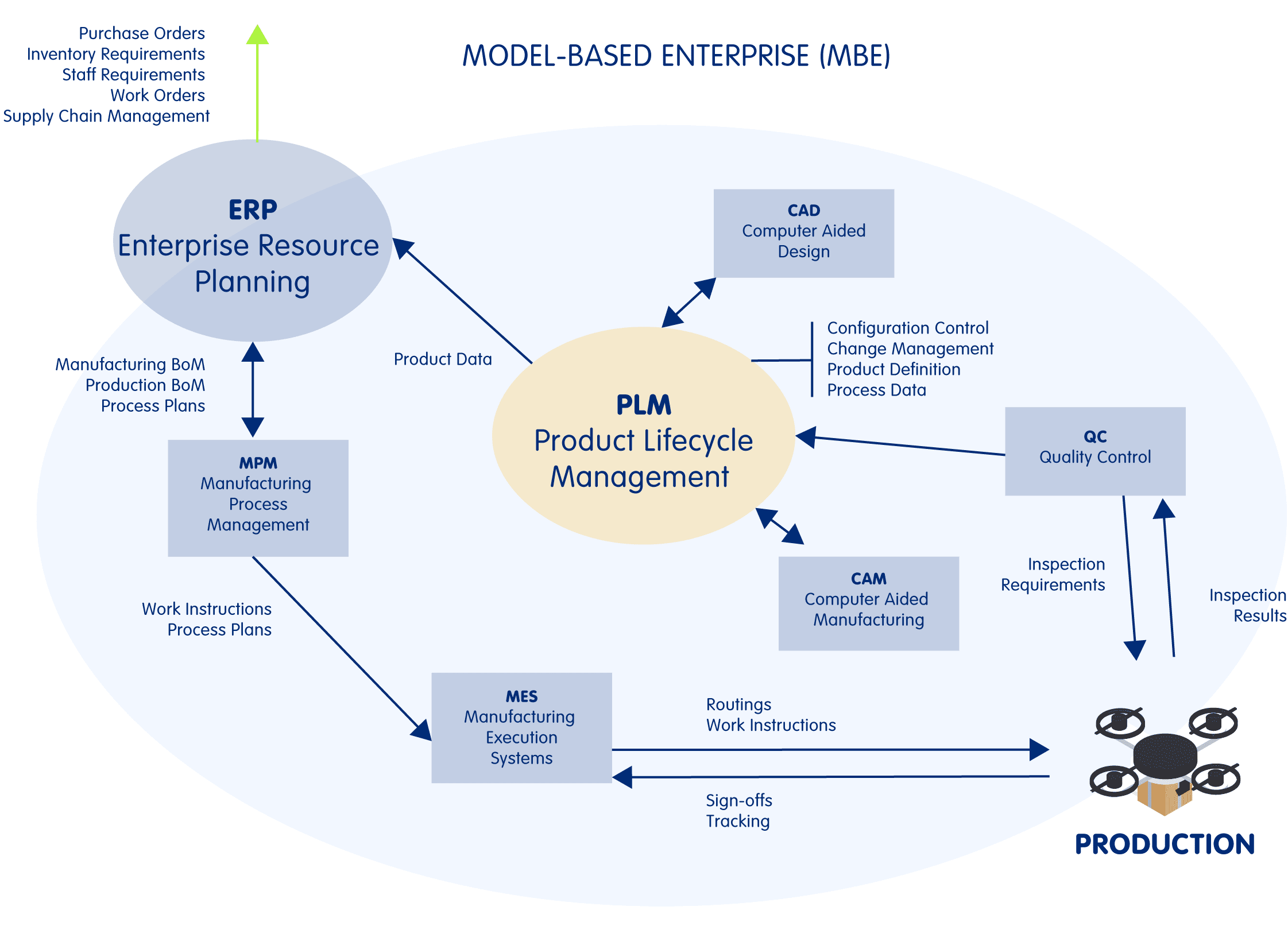

A variety of data sources can contribute to the model including data from product materials in Enterprise Resource Planning (ERP) systems, Advanced Planning and Scheduling (APS), process plans from Manufacturing Process Management (MPM) systems, work instructions from Manufacturing Execution Systems (MES) and Quality-Control (QC) systems.

Only with Product Lifecycle Management (PLM) can MBE be enabled with the lifecycle data and process management it requires. When this is done, it will create a huge leap in raising digital transformation maturity.

How the information flows

Each phase of the product lifecycle acts as a conduit for the seamless flow of information from one stage to the next, fostering a highly integrated and efficient process. It all begins with the Design phase, where digital models serve as the foundation. These models encapsulate not only the product's physical design but also its behaviour, requirements, and other crucial data. As the product transitions to the Engineering phase, this rich model-based information flows effortlessly, empowering engineers to refine designs, simulate performance, and validate feasibility.

Moving to the Manufacturing phase, the detailed digital models guide production processes, ensuring precision and consistency while minimising errors.

In the Maintenance and Service phase, these models continue to be invaluable, aiding in predictive maintenance, troubleshooting, and ensuring the product's longevity.

The feedback loop is completed as insights from real-world performance inform future design iterations, initiating a continuous cycle of improvement. In essence, MBE ensures that information flows cohesively across the product lifecycle, reducing redundancy, enhancing collaboration, and driving innovation at every step (see graphic).

The Illustration shows how you enable a Model-Based Enterprise to enable the true Digital Thread. Image courtesy of www.nist.gov

Model data becomes the core of the Digital Thread

The MBE model data serves as the vital core of the Digital Thread, knitting together a tapestry of essential components. Product Manufacturing Information (PMI), MBD, and MBSE contribute to this rich tapestry, providing a comprehensive digital representation of the product. As the product journeys through its lifecycle, from design to manufacturing and beyond, ERP systems rely on this central model data for real-time decision-making.

As we mentioned earlier, what holds this intricate web together is the PLM system, the backbone that ensures data integrity and accessibility at every phase. PLM becomes the lynchpin in MBE, facilitating seamless collaboration, reducing errors, and enabling organisations to harness the full potential of the Digital Thread. In this interconnected ecosystem, model data isn't just data; it's the lifeblood that fuels innovation and efficiency across the entire enterprise (see graphic).

Bring intelligence to your Model-Based Enterprise

As mentioned above, solid model data is key in the manufacturing and quality processes. There are many real game-changing benefits from boardroom to the factory floor of adopting MBE, however, here are some of our favourites:

- Eradicate transcribing: Engineers are no longer called upon to interpret and transcribe engineering data

- Auto create step visuals: Each instruction step has a self-generated 3D visual highlighting key information and warnings

- Collapse engineering change-time: Engineering changes that historically took months could now get executed in hours

- Improve efficiency: Digital models enable faster design iterations, reducing time-to-market. Around 3-5 % of revenue can be saved and redirected to the EBITDA line. Engineers can focus on innovating

- Enhance quality: With a single source of truth, errors and inconsistencies are minimised with accurate data sharing across the product lifecycle, with reduced errors and improved traceability

- Boost collaboration: Teams can work more cohesively across disciplines and geographies. Suppliers benefit from all the associative data by receiving rapid and accurate change notices

- Embrace innovation: Digital models open doors to advanced technologies like IoT, AI and Digital Twin

- Adapt to change: Organisations become more agile in responding to market shifts and being competitive

- Speak to the “Executive”: The solid model is no longer the property of engineering alone. It can use reporting to tell executives where to improve.

Model-Based Enterprise final thoughts

In wrapping up this exploration of the Model-Based Enterprise (MBE) and its role in the Digital Thread, we want to thank you for joining us on this journey.

Through MBE, we've seen how businesses can eradicate transcription errors, speed up engineering changes, improve efficiency, enhance quality, and boost collaboration across disciplines and geographies. They can embrace cutting-edge technologies like IoT, AI, and Digital Twin, becoming more adaptable and competitive in dynamic markets. We've also highlighted the importance of solid model data in reporting to executives, transforming the solid model from the domain of engineering alone to a valuable tool for strategic decision-making.

In essence, MBE is a game-changer that propels organisations toward greater efficiency, innovation, and success. We hope this journey through the world of MBE has been as enlightening and inspiring for you as it has been for us. As we move forward, let's continue to explore and harness the transformative potential of the Model-Based Enterprise.