Leading Australian Dairy Manufacturer Chooses ATS Global for Automation Audit at its 7 Dairy Plants

Purpose

- Understand operational risks associated with obsolete/unmaintained PLC equipment

- Prioritize capital and operational expenditure spend in-lines with quantified risk assessment for medium to long term

- Identify and consolidate spares across the country

Project Scope

- Site audit of all PLC hardware including small package plants

- Spare parts count at each site and review of firmware

- Identification of any hidden stores of parts

- Review of code for maintainability

- Assess if clients’ software, tools, cables and knowledge are available and capable to maintain PLC equipment

Solution Approach

- Facilitate site audits and introduce program review at all sites

- Create a master record of all PLC assets –country wide

- Defined criteria and rank each PLC against the criteria

- Understand impact of failure to unit / process and plant

- Seek OEM migration plans for obsolete equipment

- Risk assessment based upon above criteria for all assets

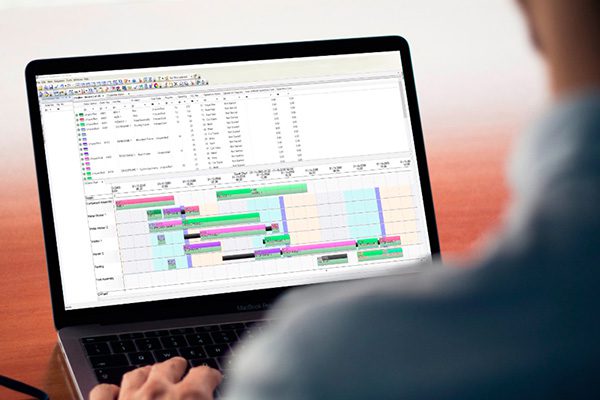

Systems & Tools

- Automation auditing and consulting

The Results

Clearly defined Business Continuity Plan (BCP) for automation equipment

Better management of spare parts across all sites. (no more hidden inventories)

Better visibility of all PLC assets including those on packaged equipment across all sites

Enabled planned maintenance/ replacement of medium / long term PLC replacements