ATS Supports a North America Based Retail Chain to Integrate OPCENTER APS

Purpose

- Insight into the real capacity of the factory

- Consolidation of applications and data sources

- Insight into impact of last-minute orders

- Possibility to respond rapidly to changes

- Ability to project seasonal sales demands

Project Scope

- Project sales demands incorporating forecasts imported directly into OPCENTER APS

- Simplify the production planning and scheduling process

- Enabling the planner to do ‘what-if’ scenarios,

- Integration with MES to send work orders to the shop floor

Solution Approach

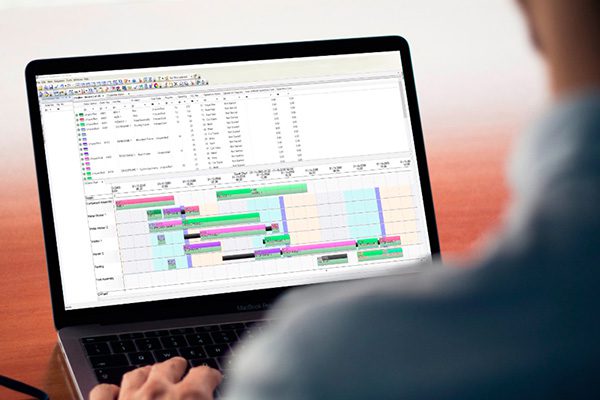

- OPCENTER APS to provide the necessary insight in production scheduling

- Tight integration with both ERP and MES to leverage the existing information in the company

- Powerful APS algorithms to create multiple planning scenario’s applicable to each situation

Systems & Tools

- OPCENTER APS software

The Results

Achieved paper-less production process

Seamless planning and scheduling between APS and MES

Enabled granular lot traceability

Complete inventory management of raw materials and finished goods