ATS Global Drives Digital Transformation at D’ANDREA SPA with Siemens Solutions

Purpose

- Transforming into a digital company while preserving traditional values helps D’Andrea maintain the legacy of Made in Italy and staying competitive globally.

- Integrating modern technologies like PLM and digital twins helped optimize production while preserving craftsmanship and quality.

- Digital transformation enables D’Andrea to compete on a global scale by leveraging technologies to improve efficiency, reduce costs, and continuously innovate.

- This not only enhances operational efficiency but also ensures consistency in the quality and identity of the product, which are fundamental elements of Made in Italy.

Solution Approach

- The integration of Teamcenter has indeed helped ensure data certainty and the validation of information within the company.

- PLM software managed the entire product lifecycle, from initial concept to end-of-life. This facilitates collaboration between different departments and users, ensuring that everyone has access to the most up-to-date and validated information. This has reduced the risk of errors and improved operational efficiency while maintaining a high level of quality.

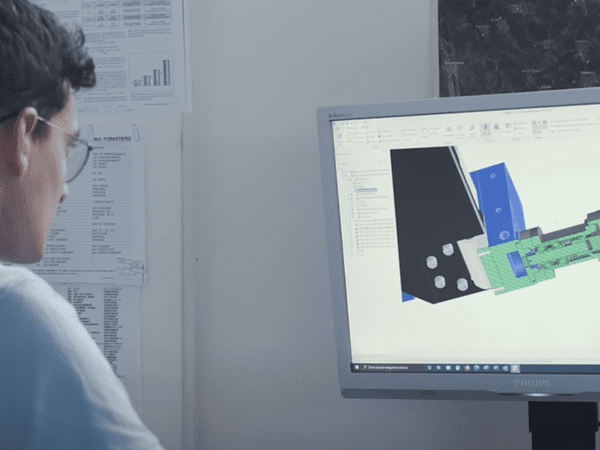

- NX CAD/CAM systems, which allow designers to create models defined by parameters and constraints PMI. This capability is crucial for maintaining design consistency and efficiency.

Systems & Tools

- Siemens Teamcenter PLM

- Siemens NX CAD/CAM

The Results

Siemens Solutions and the ATS Approach have empowered D’Andrea to transform into a fully digital company, enabling it to compete globally with industry giants.

By leveraging these advanced solutions, D’Andrea has achieved remarkable improvements:

50% Reduction in Production Time: Streamlining processes has cut production time in half.

From CAD to Production in Just 2 Hours: What once took a full day now takes only two hours, significantly accelerating time-to-market.

No Machine Downtime: The integration of digital twins ensures continuous operations without interruptions.

Enhanced Collaboration: Improved communication and collaboration across teams have fostered a more cohesive and efficient workflow.