22 January | 2 MIN READ

Real-Time Traceability for F&B with Opcenter Execution Process

In the Food & Beverage (F&B) industry, everything revolves around a delicate balance: food safety, regulatory compliance, and operational efficiency.

But that balance is increasingly difficult to maintain, as plants operate with:

- more product variations,

- shorter batch runs,

- more digital audits,

- and constant pressure to demonstrate full traceability.

The problem appears when data remains scattered across paper, Excel files, and disconnected systems.

And in critical moments – an audit, an incident, or an internal investigation – one question inevitably arises:

Can we reconstruct the entire batch, with reliable data, in minutes?

This is where data integrity and real-time traceability stop being technical topics and become a strategic requirement for the F&B sector.

A key role in this shift is played by the MES concept, capable of transforming plant execution into a coherent, fully auditable data flow.

What’s happening today in the F&B industry (and why it matters)

Before talking about solutions, it’s worth looking at what is really happening on F&B shop floors. These challenges explain why traceability and data integrity have become strategic priorities:

1. More demanding and faster audits

Auditors no longer just look at what you did, but how you documented it:

- who executed each step,

- which recipe version was approved,

- which parameters were changed, when and why,

- how each deviation was recorded.

If data doesn’t match across systems, it’s interpreted as a governance issue.

*Reference: FDA — Electronic Records (21 CFR Part 11)

https://www.fda.gov/regulatory-information/search-fda-guidance-documents

2. Smaller batches, more variations

Short campaigns, “free-from”, “eco”, “vegan” reformulations…

Flexibility is essential, but it cannot increase operational risk.

3. Silos between Production, Quality and Laboratory

Recipes, process parameters and lab results often live in separate systems…

and reconciliation happens too late.

4. Data exists — but confidence does not

Manual reports, parallel spreadsheets and delayed entries create doubt.

And when you don’t trust the data, you delay critical decisions.

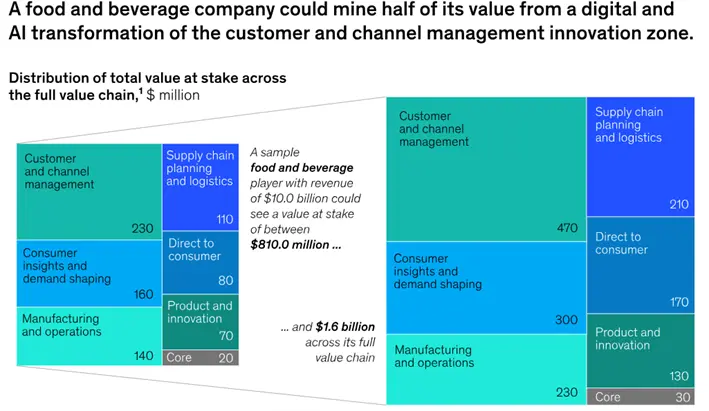

(Source: McKinsey)

The role of a modern MES in F&B

A process-oriented MES connects people, equipment and systems, creating a single, reliable digital thread that follows the batch end-to-end.

To understand the real impact of MES in F&B, it helps to see what changes in day-to-day operations. Below are the key pillars of a MES solution such as Opcenter Execution Process and how they support control, traceability, and faster decision-making.

- Standardized, controlled recipes

-

- Centralized formula management

- Version control and auditable approvals

- Only approved versions are executed on the shop floor

Result: less variability, less risk.

- Guided and validated execution

-

- Step-by-step electronic work instructions

- Inline validations (time, temperature, pressure, etc.)

- Automatic blocking when prerequisites are missing

Result: fewer human errors and fewer reworks.

- Integration with SCADA/DCS, LIMS and ERP

-

- Automatic process data capture

- Direct traceability from raw materials → batch → quality results

- Elimination of duplicate paper records

- Full batch traceability

-

- Complete batch genealogy in one click

- Evidence ready for auditors

- Faster response to incidents and recalls

*Related standard: ISO 22000

https://www.iso.org/iso-22000-food-safety-management.html

If you’d like to see how this would fit your plant, we can assess a pilot together.

Market trends in F&B driving this approach

Beyond daily operational challenges, the F&B sector is moving toward a more digital, data-driven model. These trends explain why solutions like Opcenter Execution Process are gaining relevance in the coming years:

- Data integrity as the foundation of compliance

Without trustworthy data, sustainable digitalization is impossible. - Flexibility with control

New recipes and campaign changes must be introduced without improvisation. - Efficiency and sustainability

Online controls = less waste, fewer reworks and better energy/resource usage per batch.

A realistic F&B example: before and after

In a multiproduct F&B plant, daily execution still depended on printed recipes and manual notes.

Every campaign change required manual adjustments, email coordination and late Quality reviews.

The result was predictable:

- variability between shifts,

- deviations detected too late,

- audit reports reconstructed after the fact,

- longer-than-desired lot release times.

With the deployment of Opcenter Execution Process, the change was tangible:

- recipes became versioned and controlled,

- operators received guided and validated instructions,

- process data was captured automatically,

- Quality and Production worked from the same real-time dataset.

Most importantly:

during the next audit, full batch traceability was shown in minutes, without gathering paperwork or rebuilding reports.

This kind of transition is not about “digitalizing for the sake of it”. It’s about building a trusted data foundation for stronger compliance, better operations and faster decisions.

Why ATS Global and Opcenter Execution

Choosing the right MES is only part of the journey. The real difference comes from how it’s designed, integrated and deployed. That’s where the combination of Opcenter Execution Process and ATS Global’s experience truly stands out:

- Global experience with local delivery

- Deep knowledge of F&B, Quality and Laboratory environments

- Phased approach with progressive ROI

- Robust integration aligned with industrial standards

🔗 View customer success stories

Result: lower risk, greater visibility and faster decisions.

Because when every batch is documented and traceable, the plant operates with confidence.

Frequently Asked Questions (FAQ)

👉 Want to assess the impact for your F&B plant?

We can run a diagnostic session to identify concrete opportunities and estimate real value.