For almost 30 years we have been in close partnership with international aerospace companies and their suppliers. Our vision is clear, we deploy solutions and fully integrated technologies that provide business benefits and increase plant responsiveness – always having in mind the complexity and high variances that rule your manufacturing processes.

We have developed solutions for the aerospace sector to improve the product definition and production process capability from our extensive experience in the aerospace sector. Next to our products that can be customized and also be scaled to your size of company, we provide professional consultancy, training, project management and up to 24/7 support service.

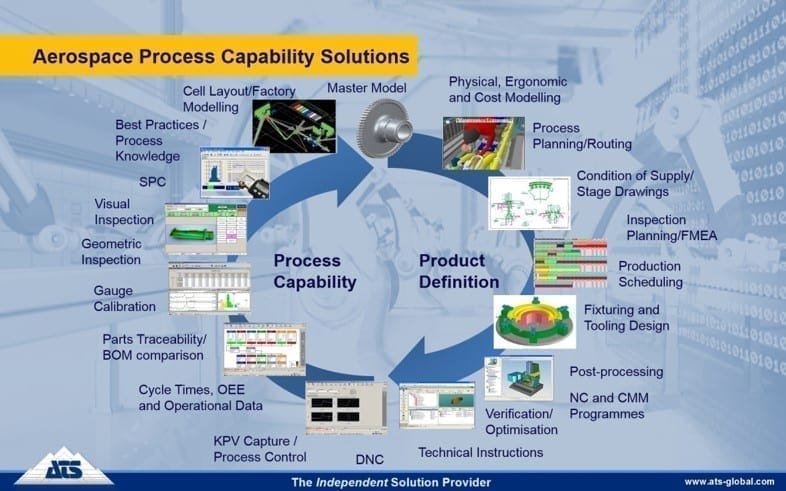

Product Definition and Process Capability

- Cell layout / factory modelling

- Master model

- Physical, ergonomic and cost modelling

- Process planning / routing

- Condition of supply / stage drawings

- Inspection planning / failure mode and effects analysis (FMEA)

- Production planning and scheduling

- Fixturing and tooling design

- Post-processing

- Computer numerical control (CNC) and coordinate measuring machine (CMM) programming

- Verification / optimisation

- Enterprise resource planning (ERP) integration

- Production order management

- Computer-aided design (CAD) / computer-aided manufacturing (CAM)

- Electronic work instructions (EWI)

- Statistical process control (SPC)

- Distributed numerical control (DNC)

- KPV capture / process control

- Overall equipment effectiveness (OEE) and key performance indicator (KPI) Analysis

- Parts traceability / bill of material (BOM) comparison

- Gauge calibration

- Geometric inspection

- Visual inspection

- Best practices / process knowledge

Are you looking for such a solutions in the engineering and shop floor area or do you want to find out more about our deployments? Then please don`t hesitate to contact us.