15 January | 2 MIN READ

Transform ASEAN Manufacturing with Intelligent Integration: The 2026 Competitive Edge

The manufacturing landscape in Southeast Asia is undergoing a seismic shift. As the region faces rapid industrialization, factory leaders are battling a major invisible enemy: the “Data Fragmentation Crisis”.

In many facilities across Thailand, Vietnam, and Indonesia, Operational Technology (OT) on the shop floor and Information Technology (IT) in the office remain disconnected. SCADA, MES, and ERP systems often operate in isolation, holding separate pieces of the puzzle but never the complete picture.

For ASEAN manufacturers, the path to Industry 4.0 is no longer just about buying new machinery—it is about Intelligent Integration.

At ATS Global, we believe the convergence of Ignition SCADA, Sepasoft MES, and Unified Namespace (UNS) architecture provides the blueprint for the future. Here is a clarified breakdown of how this modern technology stack helps companies secure a competitive advantage.

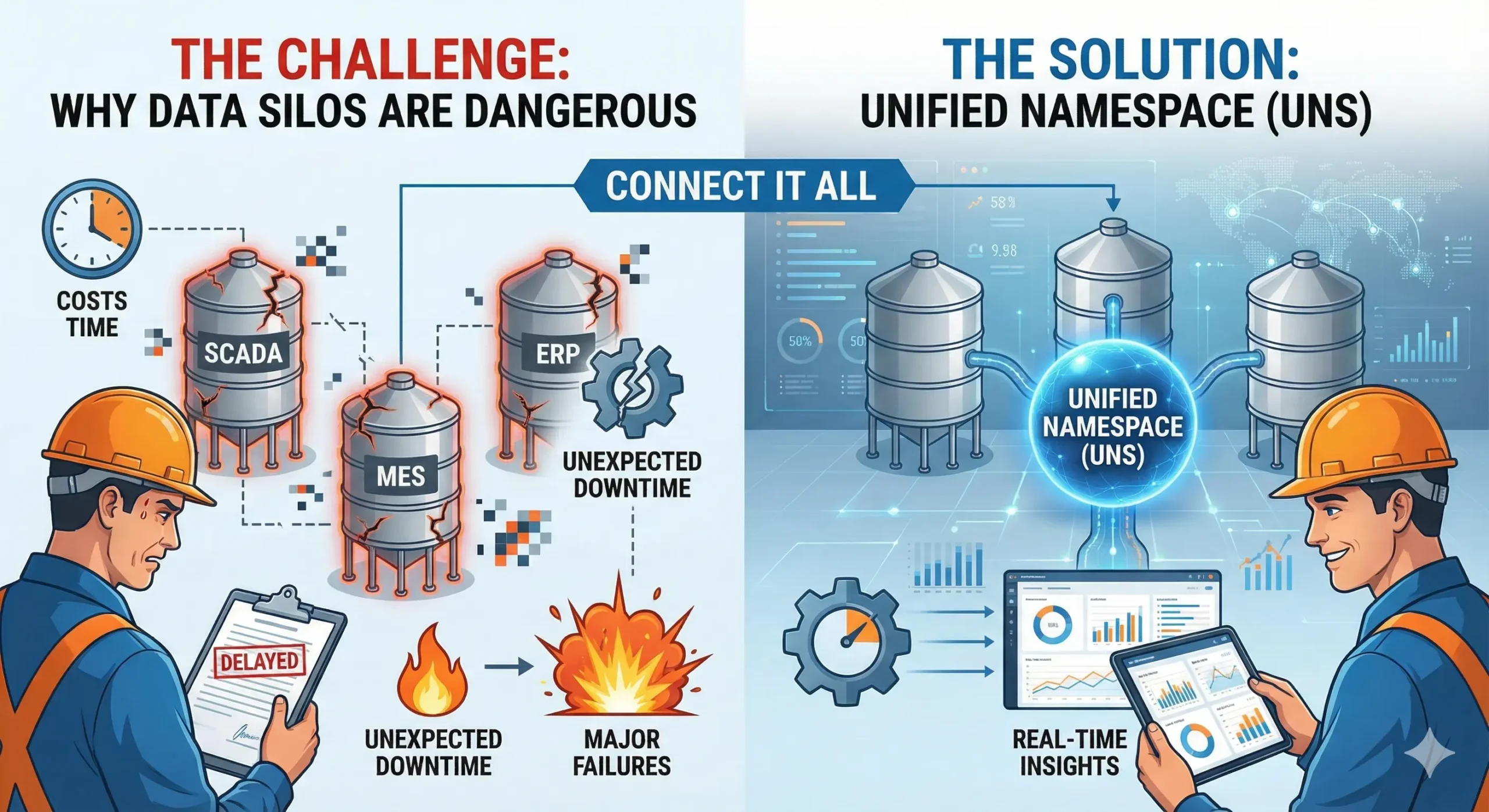

1. The Challenge: Why Data Silos are Dangerous

The Problem: Currently, factory managers often make decisions based on delayed reports and incomplete information because machine data sits in isolation. The Consequence: This fragmentation costs time, increases unexpected downtime, and allows small problems to escalate into major failures before they are detected.

The Solution: You don’t just need more software; you need a Unified Namespace (UNS) to connect it all.

Image text: The Connectivity Shift: Moving from isolated data silos that cause downtime to a Unified Namespace that empowers real-time decision making.

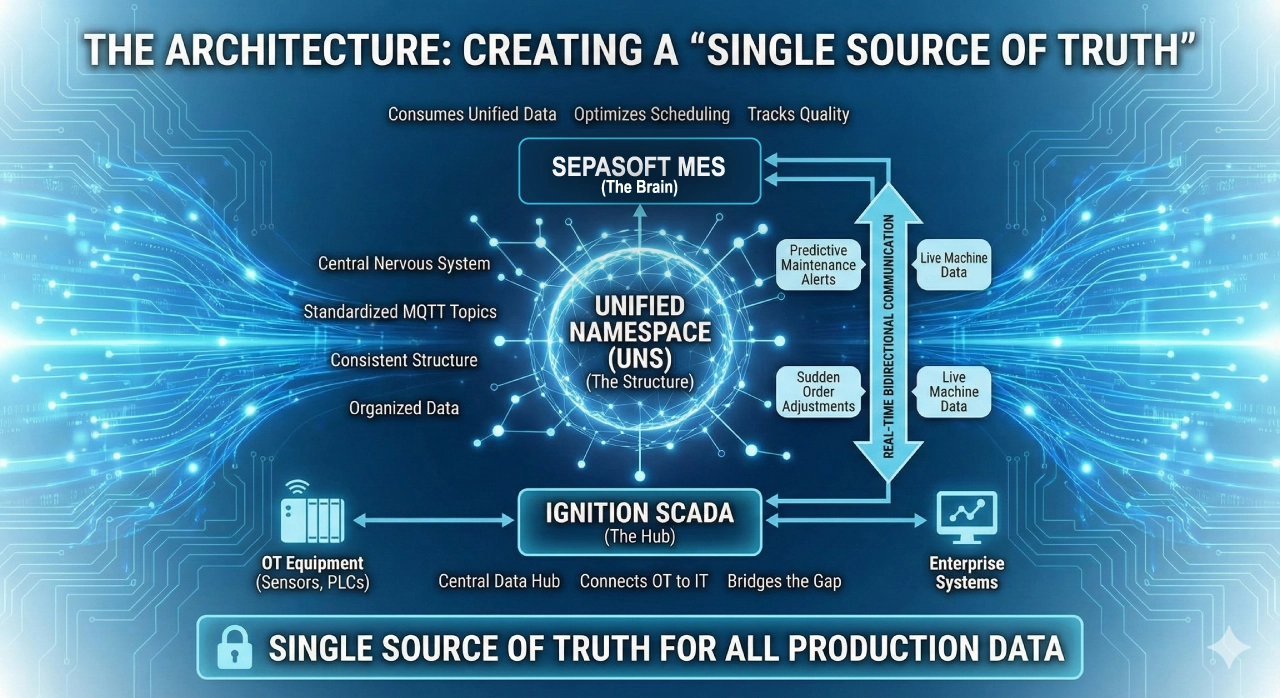

2. The Architecture: Creating a “Single Source of Truth”

To solve the fragmentation crisis, we implement an architecture that creates a single, real-time source of truth for all production data. This is achieved through three core components:

- Unified Namespace (The Structure): Think of this as the “central nervous system” of your factory. It structures live machine data through standardized MQTT topics. Instead of messy, unorganized data, UNS creates a consistent structure that every system can understand.

- Ignition SCADA (The Hub): Ignition serves as the central data hub. It connects directly to your OT equipment (sensors, PLCs) and bridges the gap to your enterprise systems.

- Sepasoft MES (The Brain): Sepasoft consumes this clean, unified data stream to perform complex tasks like optimizing production scheduling and tracking quality automatically.

Why This Matters: This setup enables bidirectional communication. It ensures that intelligent decisions made in IT systems—such as predictive maintenance alerts or sudden order adjustments—flow back to the factory floor instantly, not hours later.

Image text: The Single Source of Truth Architecture: By integrating Ignition SCADA (The Hub) and Sepasoft MES (The Brain) via a Unified Namespace, this architecture creates a consistent data structure. This enables bidirectional communication, allowing intelligent decisions from IT systems to flow back to the factory floor instantly.

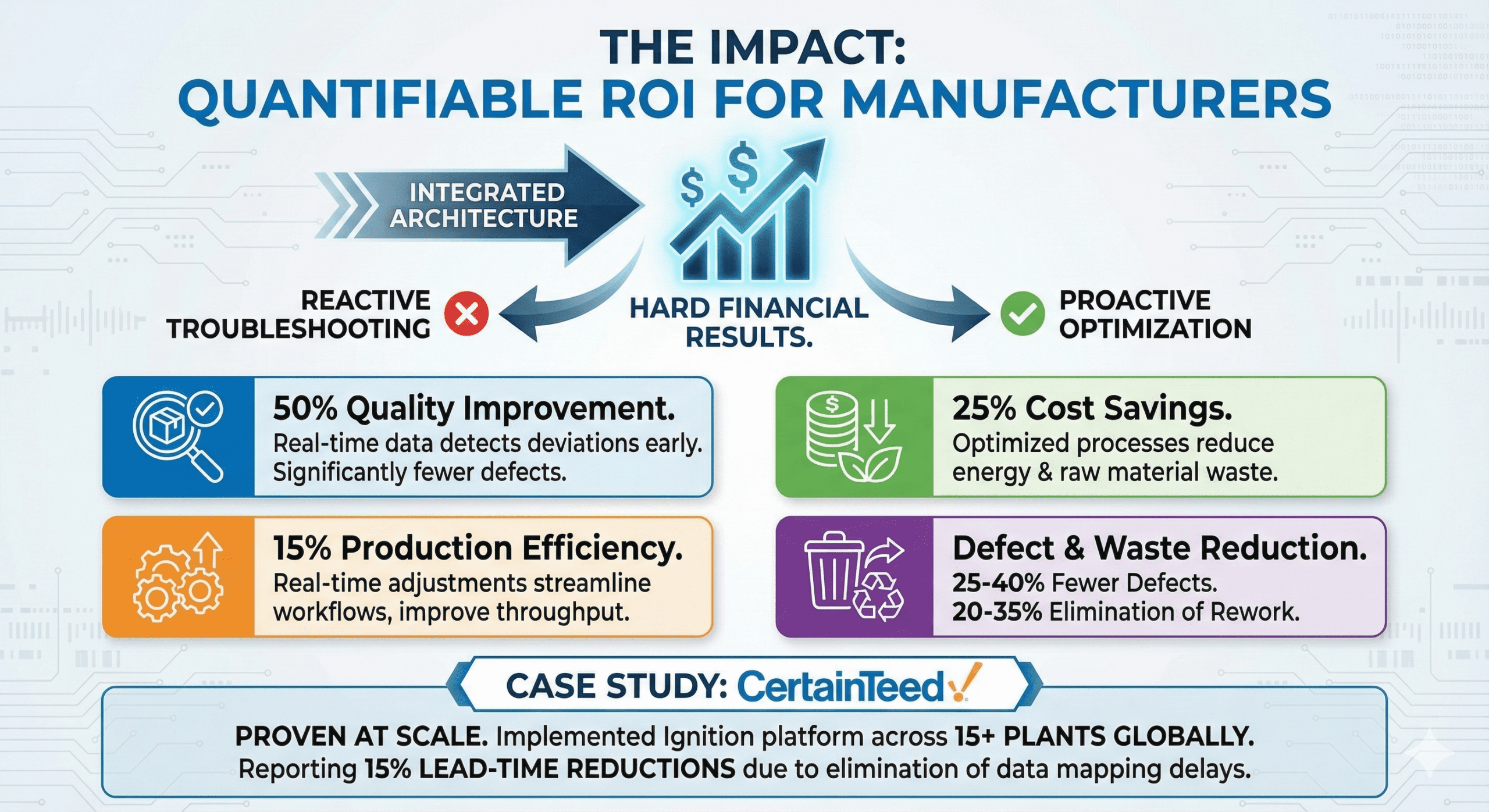

3. The Impact: Quantifiable ROI for Manufacturers

Transitioning to this integrated architecture delivers more than just “visibility”—it delivers hard financial results. By consolidating data, manufacturers can move from reactive troubleshooting to proactive optimization.

Key Performance Improvements:

- 50% Quality Improvement: Because data is real-time, deviations are detected early, leading to significantly fewer defects.

- 25% Cost Savings: Optimized processes mean reduced energy consumption and minimized raw material waste.

- 15% Production Efficiency: Real-time adjustments streamline workflows, improving overall throughput.

- Defect & Waste Reduction: Facilities typically report a 25-40% reduction in defects and a 20-35% elimination of rework.

Case Study: CertainTeed This architecture is proven at scale. CertainTeed implemented the Ignition platform across 15+ plants globally, reporting 15% lead-time reductions thanks to the elimination of data mapping delays.

Image text: Quantifiable Business Impact: Intelligent integration delivers hard financial results, including 25% cost savings and a 50% improvement in quality – proven by global leaders like CertainTeed.

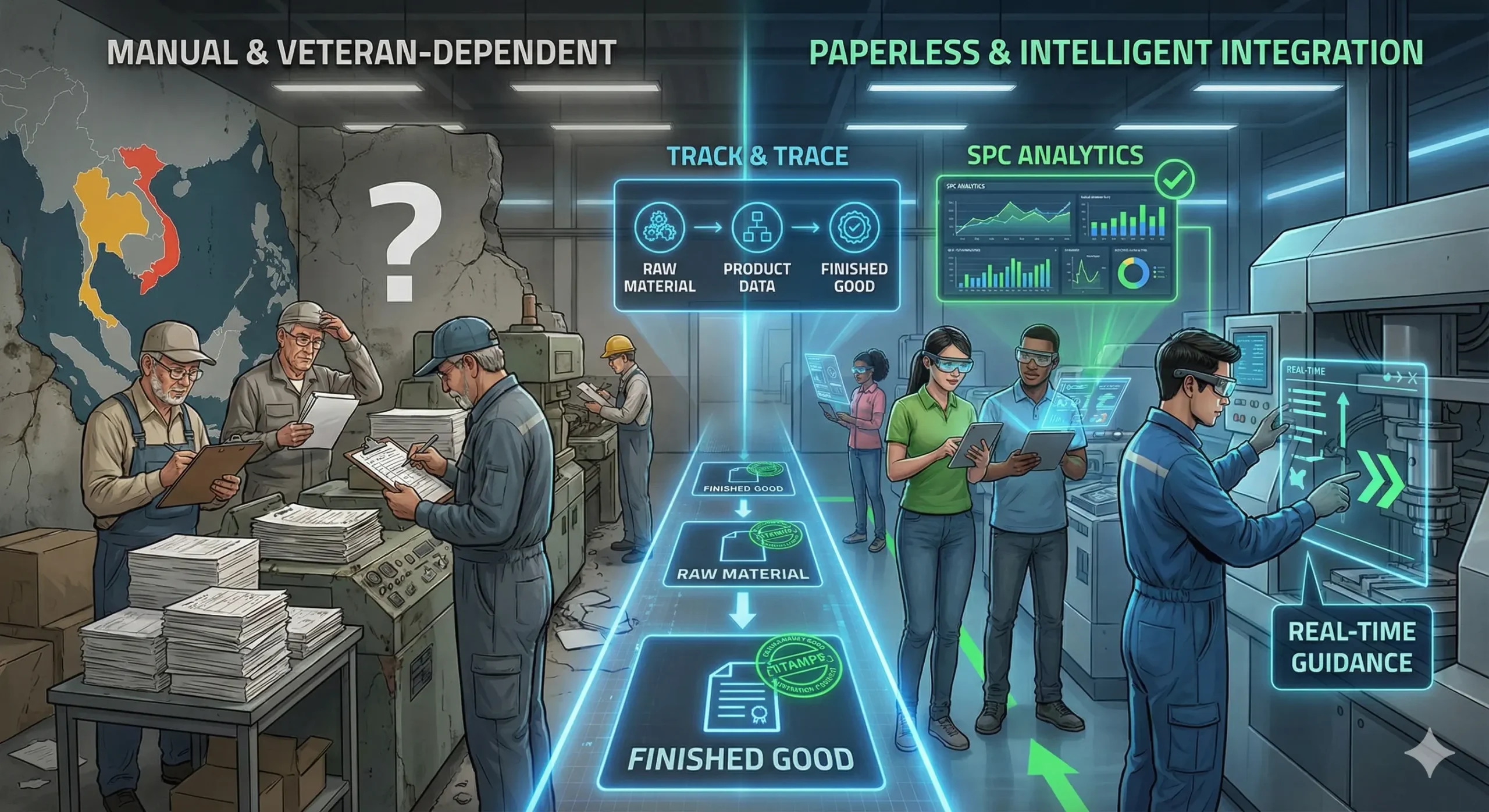

4. Overcoming the Talent Gap with Paperless Production

The Problem: ASEAN manufacturers are facing severe labor shortages (especially in Thailand and Vietnam) and quality variability due to manual processes. The Risk: Relying solely on “veteran” workers is becoming unsustainable.

The Fix: Intelligent integration reduces the dependency on deep individual experience by implementing paperless production control.

- Track & Trace: The system digitally captures the complete history of a product (genealogy) from raw material to finished good.

- SPC Analytics: Automated quality data collection removes human error from statistical analysis.

- Real-Time Guidance: The system provides automated parameter optimization, guiding less experienced workers to perform complex tasks with the precision of a veteran.

Image text: Bridging the Talent Gap: Intelligent paperless systems provide real-time guidance and automated quality checks, empowering new workers to perform with the precision of veterans—solving the critical reliance on manual experience.

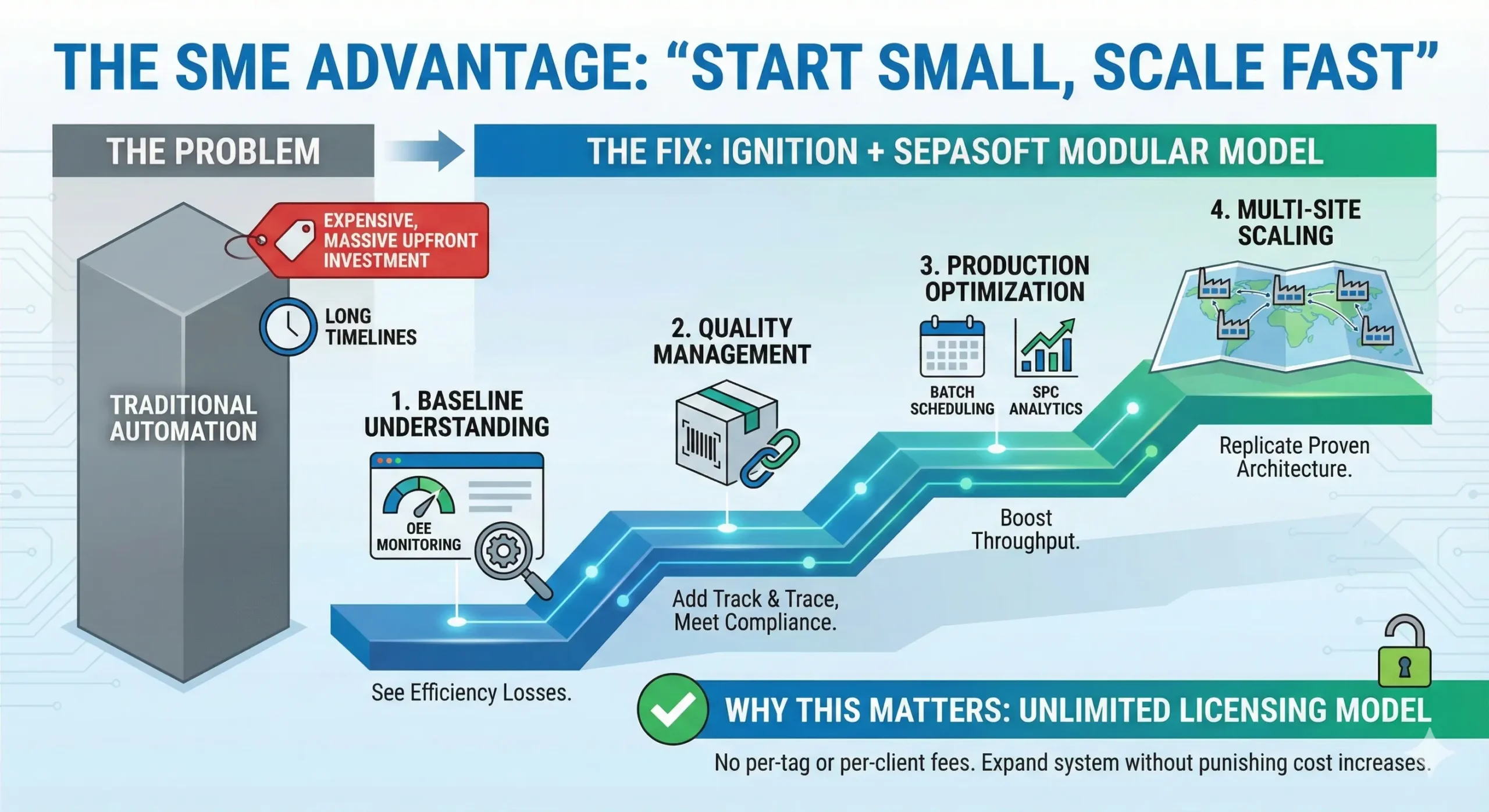

5. The SME Advantage: “Start Small, Scale Fast”

The Problem: For Small and Medium Enterprises (SMEs), traditional automation is often too expensive, requiring massive upfront investment and long timelines. The Fix: The Ignition + Sepasoft model is modular. It allows you to “Start Small, Scale Fast”

You do not need to modernize the entire factory at once. You can follow a step-by-step path:

- Baseline Understanding: Start simply with OEE monitoring to see where you are losing efficiency.

- Quality Management: Add Track & Trace capabilities to meet regulatory compliance.

- Production Optimization: Later, integrate batch scheduling and SPC analytics to boost throughput.

- Multi-Site Scaling: Finally, replicate this proven architecture across other lines or facilities.

Why This Matters: Ignition’s unlimited licensing model means you don’t pay per-tag or per-client fees. You can expand your system without facing punishing cost increases.

Image text: The Scalable Path for SMEs: Avoid massive upfront costs with a modular approach. Start with OEE monitoring and progressively add capabilities like Quality and Scheduling. Ignition’s unlimited licensing ensures you can scale to multiple sites without punishing fee increases.

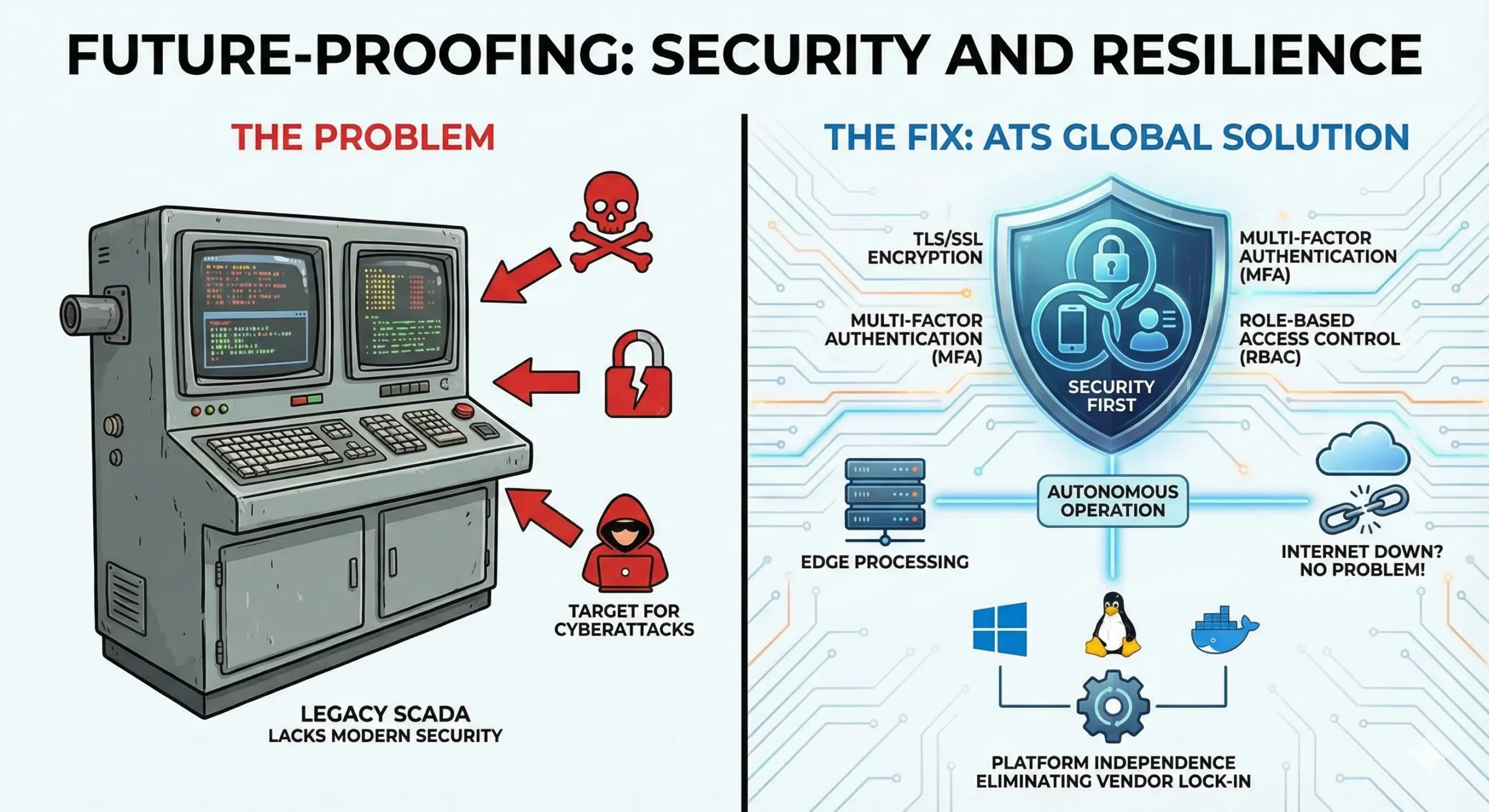

6. Future-Proofing: Security and Resilience

The Problem: As you digitize, you become a target for cyberattacks. Legacy SCADA systems often lack modern security. The Fix: The ATS Global solution is designed for Enterprise Security and Cloud-Hybrid flexibility.

- Security First: The platform is built with TLS/SSL encryption, multi-factor authentication (MFA), and role-based access control (RBAC) to protect your data.

- Resilience (Edge Computing): The system supports “Edge processing,” meaning your local facility keeps running autonomously even if the internet connection goes down—a critical feature for areas with developing infrastructure.

- Platform Independence: Ignition works on Windows, Linux, or Docker, eliminating “vendor lock-in” to specific hardware.

Image text: Securing Your Future: Don’t let vulnerable legacy SCADA systems hold you back. The ATS Global solution provides enterprise-grade security (Encryption, MFA, RBAC), ensures operational resilience with Edge processing, and offers true platform independence to eliminate vendor lock-in.

Why Partner with ATS Global?

The window for transformation is closing. Statistics show that 70% of regional businesses in ASEAN are already planning supply chain digitalization. Delaying modernization is a risk you cannot afford.

ATS Global combines technical excellence with regional expertise to deliver results:

- Global Expertise: We are the largest enterprise integrator for Ignition SCADA globally, with 30+ years of experience.

- Regional Presence: Our local teams understand the specific regulations and operational challenges of the ASEAN business environment.

- Transparent Economics: We use an unlimited licensing model to ensure budget predictability.

Ready to transform from cost competition to innovation leadership?

Just fill out the form below, and the team will hurry to contact you back ASAP!