The Smart Industry Readiness Index

Smart manufacturing is a constantly evolving space. There are countless technologies promising to improve the overall efficiency and effectiveness of each operational aspect- inventory, supply chain, assembly, production, asset management, quality management, inspection, planning, etc. Such a technological abundance can lead to confusion amongst customers with so many solution providers promising a digital transformation of their plants.

However, the fear of being left behind the technological curve and losing out to competition is driving organizations across the discrete and process industries to implement these technologies.

But before they can start on their smart manufacturing journey they must answer some basic questions:

- Does my organization have the necessary Information Technology (IT) and Operational Technology (OT) set-up to implement Smart Manufacturing technologies?

- What is the optimal mix of technologies suitable for my size of operations?

- What is the practical payback period / return on investment (RoI) for my investment in Smart Manufacturing?

- Do I have the processes in place to benefit from smart technologies?

- Is the culture of my plant ready for smart manufacturing?

ATS Global is the Independent Solution Provider for Smart Digital Transformation. We help manufacturers to assess and raise their manufacturing maturity level and we are on constant look-out for industry best practices to address our customer’s concerns. One such expert recommendation to address the challenges mentioned above came in the form of the “Smart Industry Readiness Index”. This study was conducted by The Singapore Economic Development Board in partnership with TÜV SÜD and was validated by an advisory panel of industry and academic experts.

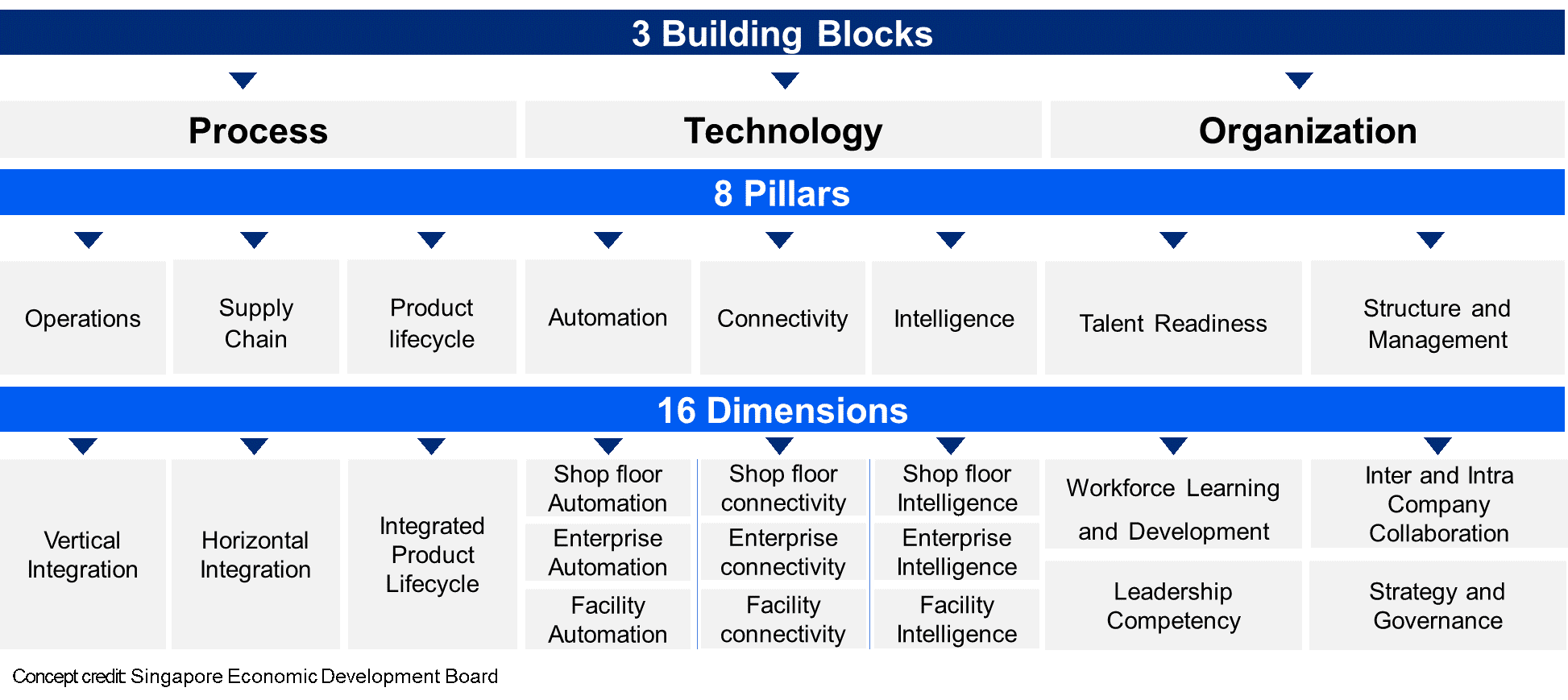

The Smart Industry Readiness Index is a step-by-step guide that enables manufacturers to assess their readiness for Smart Manufacturing. It adopts a questionnaire-based approach to evaluate the relative readiness of various operational aspects of the plant by simplifying them along 3 building blocks, 8 pillars and 16 dimensions.

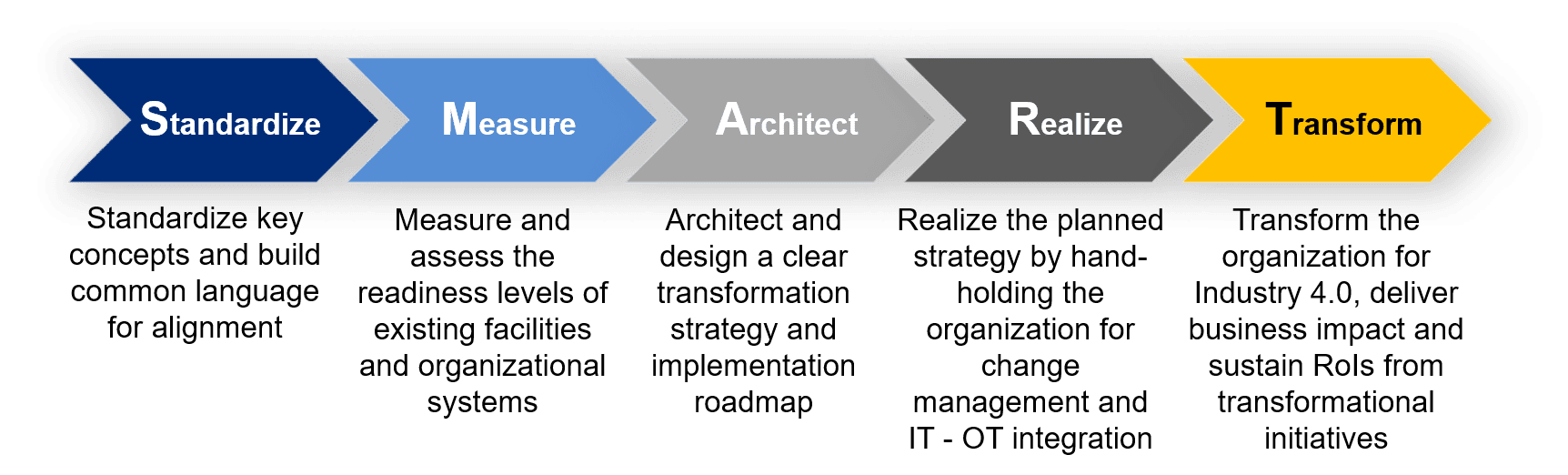

We have leveraged the above index to develop a comprehensive framework to help organizations assess their maturity for smart manufacturing. We call it the SMART framework. It comprises of 5 distinct elements – Standardize, Measure, Architect, Realize and Transform.

- The SMART framework is specially designed to help manufacturers improve their maturity level for Smart Manufacturing by following a practical approach to digital transformation.

- The first two elements of (Standardize and Measure) help organizations to streamline their vision and establish realistic goals for digital transformation. The ‘Standardize’ element helps organizations develop a common language and approach towards the whole assessment process. The ‘Measure’ element focuses on conducting a detailed readiness assessment in line with the Smart Industry Readiness Index.

- The other 3 elements (Architect, Realize and Transform) focus on designing the digital transformation strategy, implementing the plan by IT/OT convergence, change management and realizing Return on Investment for the customer. By leveraging our global experience in 15+ industries we can cross-pollinate best practices in digital transformation.