ATS Rapid MOM- A Launchpad for Digitalisation Journey

Digitalisation is a reality! While large corporations are talking about arriving at a minimum digital standard across their supply chain, Small and Medium Enterprises (SMEs) are waking up to the reality that this is the ‘only’ way forward!

Modern day Manufacturing Execution Systems (MES) or Manufacturing Operations Management (MOM) solutions bring tangible business value. They help to seamlessly manage shop-floor manufacturing operations, production, quality, inventory and maintenance.

The Benefits of Digitalization

Some of the benefits manufacturers across the globe are realizing with digitalization include:

- Reducing risk of production errors

- Meeting regulation and traceability requirements

- Improving efficiency while reducing cycle time

- Reducing waste and scrap

- Supporting efficient product customization to accelerate New Product Introduction

- Reducing total cost of ownership and improving profit margins

- Removing paper from the shop floor

Barriers to Adoption

Despite the widely known paybacks, the technological adoption of digital transformation solutions like MES/MOM is slow. Given the current economic uncertainties and rapidly changing technological landscape, SMEs are reluctant to commit resources (capital, time and people) for any widespread digitalization initiative. Three of the main roadblocks for Digital Transformation initiatives for SMEs are:

- Justifying tangible Return on Investment (RoI).

- Getting the optimal digital transformation modules/ applications that are deployable and useable.

- Time required to implement and realize benefits from digitalization initiatives.

A Solution Built on Experience

At ATS Global, we leveraged our combined experience of delivering 1500+ MES/MOM projects across the globe to develop a rapidly deployable and scalable MES/MOM solution- The Rapid MOM.

The solution is designed to have a very short learning curve and users do not require special IT expertise to handle the solution. It is a cost-effective solution that prevents organization from acquiring ‘MES/MOM shelfware’ modules that they do not require or end up underutilizing. Remember all those ERP modules that are installed in your organization and are hardly used or considered in information plans?

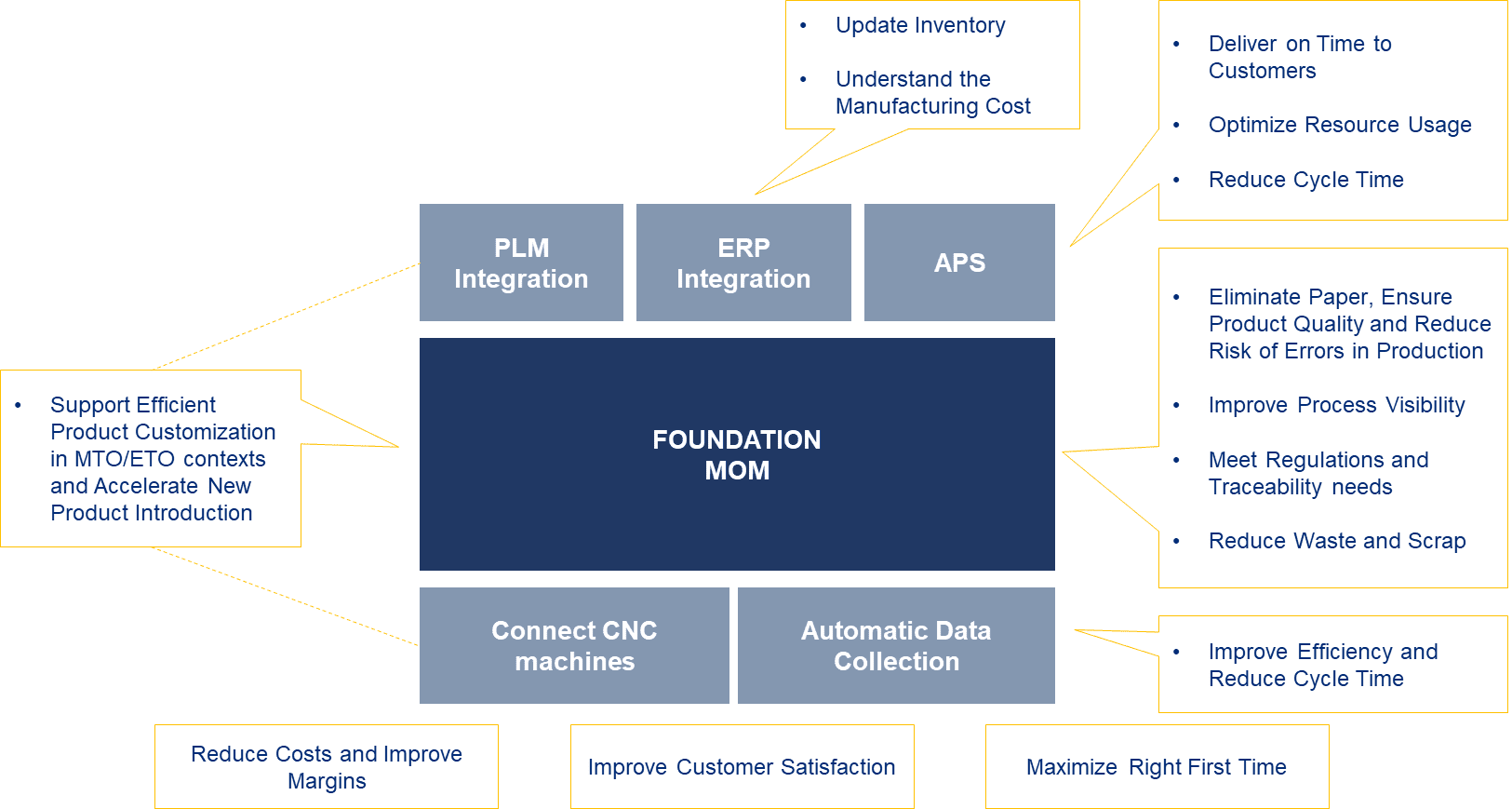

Rapid MOM operates on the principles of a Foundation MES/MOM that covers the basic building blocks required to create a sustainable digitalization ecosystem. This foundation is subsequently augmented with modular packages / applications based on the organization’s requirements.

Additional Modules of Rapid MES/MOM

Foundation MES/MOM is the stepping stone for a digital enterprise. Rapid MOM is all about getting the Framework MES/MOM solution deployed and live at the earliest. It is then integrated into the existing application landscape in subsequent phases. These modules can seamlessly integrate with the Foundation MES/MOM.

- PLM Integration

If your organization has a defined PLM tool that defines the lifecycle of the product, chances are you have a strong digital thread from design to production. The PLM Integration module will help you to further extend the digital thread into the production world. For example, with this integration, you may download production process information directly to your MES/MOM.

PLM integration is key to a multi-product set-up where customizations and rapid time-to-market is key to competitive advantage. - ERP Integration

The ERP system usually holds the key to production orders. It is the one system that at times integrates with everything from inventory to dispatch and beyond. With ERP integration you can directly download a list of production orders to be executed in your MES/MOM application. This fully automated data transfer reduces the chances of human error in production processes. The ERP integration also enables you to assess finished goods and update the inventory in ERP accordingly. - Planning and Scheduling Module

Dynamic planning and scheduling of resources is the backbone of efficient production processes. Robust scheduling tells the production facility about the resources that need to be available to meet utilization, delivery performance and efficiency parameters. It is generally used by manufacturers that need to schedule machines and other resources like materials but it is also used for scheduling manual labor such as assembly, service or value-added logistics. The planning and scheduling module helps to plan production, allocate resources and define the optimal schedule. - Connect MES/MOM to CNC Machines

This module is especially beneficial for discrete manufacturing organizations. The integration of MES/MOM with CNC machines helps to dispatch part programs and recipes automatically to the right machine at the right time, based on the current Work Order. - Collect Machine data for Overall Equipment Effectiveness (OEE)

Analysis of equipment downtime and performance can be done effectively if organizations collect the data directly from the equipment. Integration of the MES/MOM layer with the control layer (PLC, DCS, SCADA/HMI) helps to directly calculate crucial information to support effective maintenance operations.

Foundation MES/MOM

Foundation MES/MOM covers the basic elements of a MES/MOM solution. It provides the minimum framework and structure required to execute the information flow in production environment. Some of the aspects covered by Foundation MES/MOM include:

- Production Process and Flow Control

Foundation MES/MOM enables the organization to define the manufacturing processes in a digital environment. It helps to manage Work Orders and provide instructions to operators on screens and tablets. This helps to control and standardize work orders generally created locally in discrete packets/ silos. The information is then subsequently dispatched to the right people, at the right time, in the right place. - Material Management

In addition to the production process management and streamlining of process orders, SMEs experience a major challenge in managing material information. Often, the material information flow is driven by a paper-based system. The operators follow heuristic approaches towards material consumption. For example, in discrete manufacturing, the operator replaces the machine tools based on their judgement. With Foundation MES/MOM, organizations are able to trace material consumption and tool usage and validate the assembly of critical components. - Tracking and Genealogy

With information integrated in Foundation MES/MOM, production activities and quality data are electronically declared and registered. This helps to create a less-paper production process if not a fully paperless shop-floor. In addition to this, it provides complete traceability, real-time updates of production status and standard system-driven reports to track KPIs. - Non-Conformance Management

Organizations can leverage the integrated information availability to trace defects and quality issues more effectively. This helps to prevent defective products from leaving the factory. As the order processing occurs through Foundation MES/MOM, the quality/inspection department can hold the order for shipping until repairs are completed. This helps to manage non-conformance issues and helps to maintain regulatory compliance.

Digitalization Today

ATS Rapid MOM is an intuitive and easy-to-use system addressing most common manufacturing usage scenarios with minimal requirements.

Digitalization is not tomorrow… it is today… NOW!

In December 2018, LNS Research published an interesting study on “Understanding Industrial Transformation Today: Digital Readiness is the Foundation for Success”. One of the key findings of this survey was that “A solid IT / OT foundation is a key indicator of digital readiness for Industrial Transformation.” Rapid MOM is a reliable means to implement digitalization with optimal resource commitments. The road to Smart Manufacturing or Industry 4.0 travels through MES/MOM.

Remember to assess your organization’s readiness using the Smart Manufacturing Assess toolkit.

About ATS Global

ATS Global is The Independent Solution Provider for Smart Digital Transformation. Since 1986, ATS has been undertaking continuous improvement initiatives and manufacturing IT solution design, deployment and 24/7 support assignments delivering tangible business value to customers world-wide.

To find out more about ATS Rapid MOM visit https://www.ats-global.com/solutions/rapid-mom/

Are You Ready?

A maturity analysis of your current production processes is the first and most important step in any digitalization journey. It helps you to visualize ‘as-is’ and ‘to-be’ states of digitalization in your organization. It also establishes the ground-rules for the initiative such as your vision, short-term/ tactical goals, long-term/strategic ambitions and key success factors.

Robbert has 9 years of experience in leading the design, development and deployment of MOM solutions at large manufacturers globally.

As MOM Consultant, Robbert delivers consultancy services to manufacturers in different industries, to support them in their manufacturing digitalization journey.

Besides consultancy, Robbert is responsible for the MES Engineering team at the US division of ATS. A smoothly operating team of professionals is key to provide excellent engineering services to our customers.

Robbert is certified by MESA International through the Global Education Program.

Robbert can be typed as structured and pragmatic, good listener and broad thinking. A team player with attention to the details

Want to conduct a Smart Readiness Assessment of your organization?

Here’s a free toolkit to assess how prepared your organization is for smart manufacturing!