A Digital Transformation of Your Foundry

Quality Inspections

How do you drive down your scrap and rework rates to reduce your Cost of Quality? If you are using outdated methods to collect and analyze your quality data, making a real impact is difficult.

ATS Inspect gives you the flexibility to respond to changing demands so that high quality is built into your casting processes, rather than a metric you’re constantly chasing. With real-time quality alerts and analysis, you have everything you need to maintain your brand as you diversify and adapt your products.

Product quality inspection software for the Casting industry. Eliminate paper checklists, improve product quality and reduce the Cost of Poor Quality.

Benefits at Every Stage

Casting

Used at Quality Gates throughout casting processes to reduce non-conforming material passing between processes.

Finishing and Rework

Used throughout finishing and rework processes to capture defect, repair and weld and blend information.

Customer Returns

Correlate customer reported defects and returns with your internal data to drive process and containment improvements

Get in touch to discuss

the future of your casting inspections

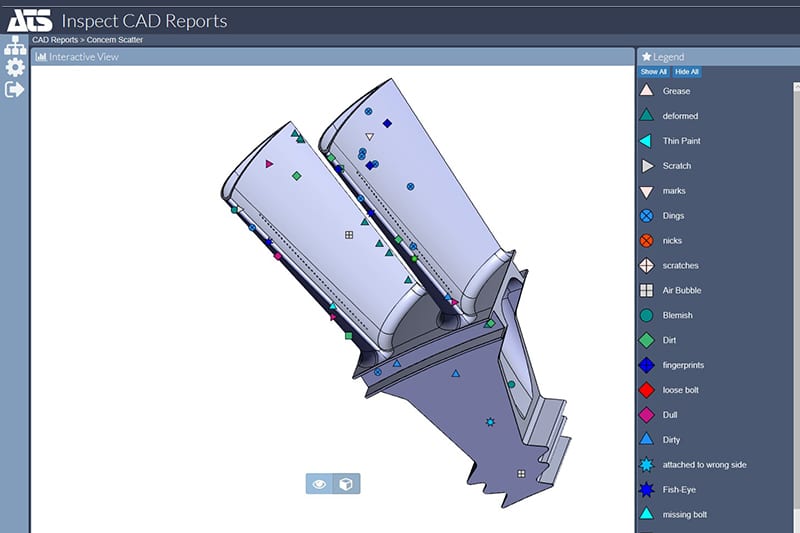

Interactive Inspections

Using a tablet or PC, operators place defects directly onto an image of your product or onto its 3D Digital Twin, so that the precise location can be recorded.

ATS Inspect eliminates the wasted man hours and unnecessary errors produced when transcribing paper tic sheets. Inspections are recorded directly into the system so that all data becomes available for reporting and analysis in real-time.

Automated Inspections

ATS Inspect links to your shop floor equipment so that it can report and analyse the results from your automated test equipment alongside your manual inspections.

By integrating quality data from all sources, ATS Inspect provides a complete overview of your plant quality whilst also allowing you to view the complete inspection history of each individual unit.

Digital Checklist

The checklist guides operators through a list of specific items to check such as nugget size/cut and can be used for score destruct audits.

Measurements can be keyed in or sent electronically from a digital caliper or other device.

Measurements that are out of spec are automatically highlighted.

Real-Time Reporting and Analysis

You can access web based reports such as pareto charts of your top defect producing parts, individual part inspection records and other valuable analysis on a real-time basis.

ATS Inspect also provides aggregate reports that take multiple inspection records for a given part and instantly overlay all the defects entered against those parts to produce defect maps, scatter and concentration diagrams.

Quality Alerts

Let the right people know right away when quality issues arise such as a series of units with excess flash or too much porosity in a specific unit. Automated emails and live information on overhead displays on the factory floor allow action to be taken immediately.

In real time, ATS Inspect reduces non-conforming material in your Work In Process, and also drives long-term process improvements.

Let’s talk! Enter your info below

and we will contact you to discuss your application