The new Microflow PC is a PC-driven air-electronic flowmeter for the comparative measurement of small through holes in rubber, plastic, metal, ceramic and composite materials. The Microflow has 2 x air outlets, which can be used simultaneously or independently for varying hole sizes. All measurements are comparative to a known size or area.

Features and Benefits

- Fast, efficient and accurate means of measuring small holes with low-pressure air

- Built-in air filtration and regulation thus providing a plug and play instrument

- Steel enclosure protected for shop-floor use

- Built in Data Collection and SPC

- PLC control output and footswitch port

- USB and Networking ports

Utilised within the pharmaceutical, plastics, aerosol, automotive, fuel, gas and many more industries

Overview

- Hole diameters of 0.157′ (4mm) or smaller are very difficult if not

impossible to inspect with mechanical gauges or non-contact inspection

equipment. Microflow is designed to quickly measure holes “comparatively‘

down to 0.002′ (0.05mm) - This instrument combines the speed, accuracy and versatility of electronics

with all of the performance attributed to pneumatics - Microflow performs very quickly and provides extremely accurate

comparative measurement. - Low 138mb output pressure allows inspection of soft or flexible

components without distortion. Minimised shop air consumption - Dramatically improves inspection throughput

- Dimensions: 400mm H x 200mm W x 200mm D – Minimum space required to

position on work benches or to be installed in automated in-process

inspection - Easy to see status changes indicated in

GREEN – Acceptable range

AMBER – Warning range

RED – Reject - Configurable screen. Displays Menu Functions including Calibration

Instructions - Makes setup quick and accurate. Provides durability in shopfloor environment

- No knobs or switches to be changed or adjusted during production cycle

- Plug and Play solution with accurate air pressure adjustments

- Switchable between single output by pressing the red button on the front or

continuous data-send - Output a relay electrical signal for PLC control or connection to footswitch.

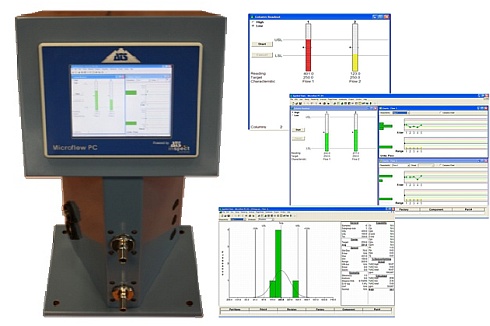

ATS Microflow PC and screenshots

Typical components measured by the Microflow PC

Data Collection and SPC

The Microflow uses the same air system as the Flexair 1 and 2 flowmeters, but now offers a full-functional data collection and SPC package. Measurements can be stored and analysed using the pre-installed ATS Inspect VDC software.

‘Live’ column displays are used in order to immediately identify the measurement status. For example, red, green and yellow bars appear depending upon the tolerance settings. The column display can also be changed to appear in grid format. Label information can also be entered prior to measurements, for example; user name, shift, part type, colour, batch # etc.

ATS Inspect VDC

It is a module from a fast evolving suite of software modules for shopfloor and laboratory data collection. VDC is fully configurable software module with ergonomics to suit both the user and process. Charting can be displayed adjacent to the measurement display to show a real-time view of the process.

The Microflow PC has a network port available in order to connect to a LAN. The

reporting module allows the drill-down reporting and charting for traceability studies.