Automotive OEM reduces warranty claims with digital transformation of quality processes.

Purpose

This OEM customer, based in the US, needed to reduce the number of warranty claims they were receiving while also tackling the growing challenges of mass customization across the supply chain.

To achieve this they wanted to carry out a digital transformation of their quality processes using a solution that would allow them to do the following:

- Eliminate paper inspection forms.

- Feedback quality issues to point of origin.

- Improve quality traceability.

- Utilise dynamically updating checklists.

- Create defects automatically based on data received from vision systems.

- Exchange data with the existing MES.

They chose to implement ATS Inspect which gave them all of this and much more.

Solution Approach

Implementation at Essential Gating Points

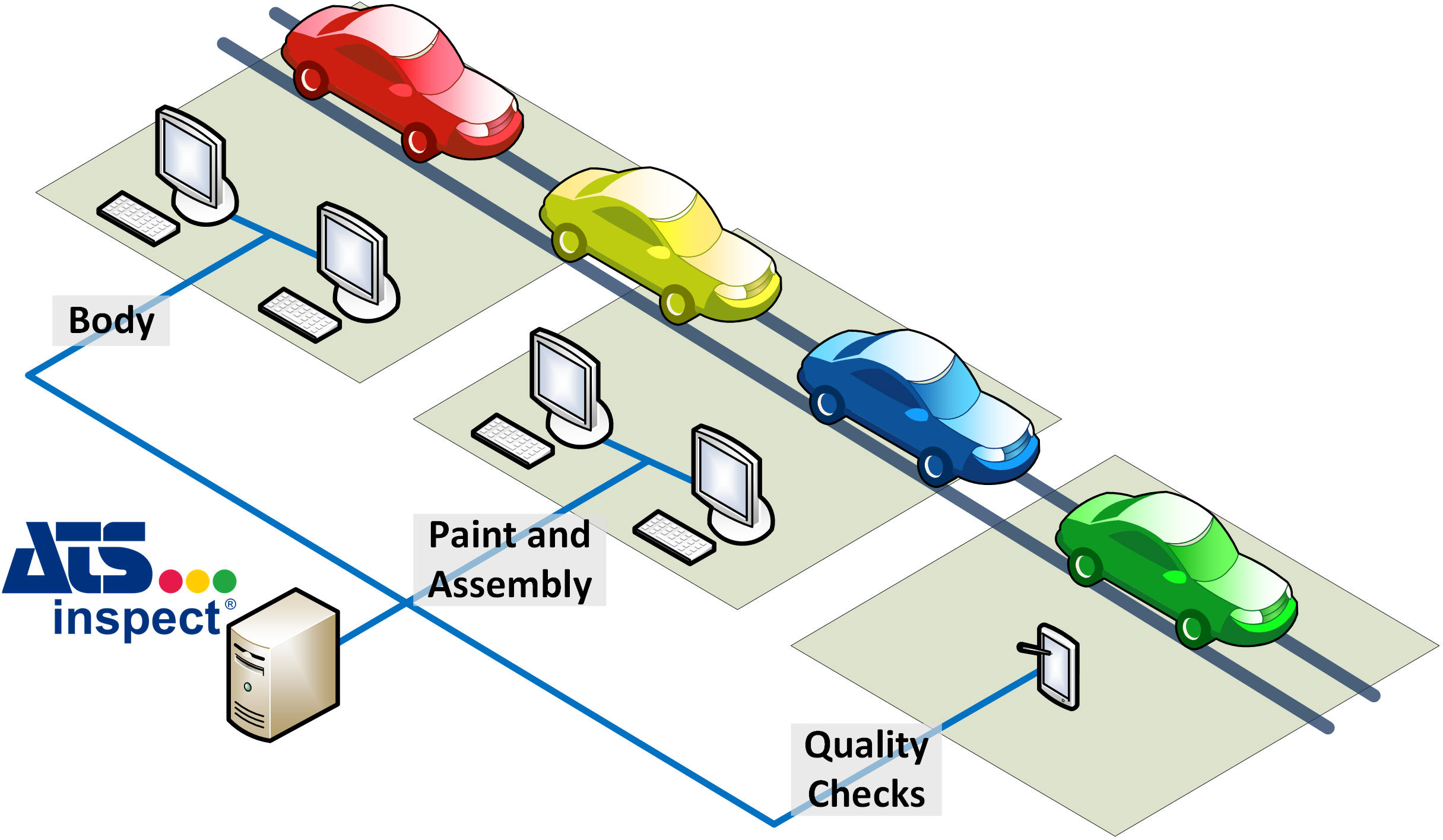

ATS Inspect has been deployed to keep quality in check in the Body, Paint and Assembly (Trim and Chassis), Automated Test and Quality Check areas. It’s being used at over 230 stations (a mixture of PCs and tablets) to carry out visual inspections, repairs, and option checks.

Checking All Attributes

ATS Inspect records attribute data in a number of ways which allows it to carry out a complete inspection of the vehicle.

Visual defects are highlighted directly on images of the vehicle making a fast and accurate record while checklist questions are asked at each step of the inspection process. This ensures that each inspector confirms that all of the correct components are assembled and are working correctly.

The list of questions and possible answers is adjusted dynamically for each vehicle on the line so that all build options are taken into consideration. The build options are sent directly from the Manufacturing Execution System (MES).

If a misbuilt or incorrect option is detected the unit is flagged for repair, an alarm may be sent to the production supervisor and a message will appear on the Andon board in the production area where the defect was created.

The final quality gate verifies that all non-conformances have been addressed, all mandatory inspections completed satisfactorily and all automated tests are passed before releasing the vehicle to the shipping yard.

Quality Traceability

ATS Inspect also receives variable values automatically from a large number of test equipment.

This includes values such as door closure effort, CO2 emissions, battery voltage and wheel alignment. A pass/fail result for each item will be recorded for each vehicle along with the specific values of the test.

In addition, serial numbers for airbags, engine, transmission and other components are recorded for traceability purposes. This historic information is available to minimize the number of recall units in case of an issue.

Automatic Defect Creation

ATS Inspect is able to allocate defects automatically based on information and X/Y coordinates received directly from the production line test equipment.

For example, when checking for water leaks they use the Quadrascan® system which uses a speaker that emits a sound within the vehicle. Several microphones on robotic arms then follow the seams of the vehicle and can detect potential leaks in the car by the way the sound is received.

When a potential leak is found the exact X/Y coordinates are sent to ATS Inspect which then records the defect on an image of the unit, exactly in the location that Quadrascan indicated. This precision makes the repair process more effective, and provides graphical reports that allow the engineering team to find the root cause of the problem much quicker.

Feedback to Point of Origin

The faster information on quality issues is relayed back to the cell or area responsible for them, the faster measures can be taken to resolve the issues. The faster the issues are resolved, the more time and money are saved.

ATS Inspect helps in this area by generating reports that are fed to Andon boards on the factory floor. A set of custom reports are cycled through that are tailored for each cell or area.

In some cells an overview of the vehicle currently being reviewed is shown, giving the operator all the information they need at a glance to easily decide whether the unit should be sent to repair bay or the next step in assembly.

Integration with Local Systems

ATS Inspect is linked directly to the production scheduling systems. It receives the VIN number and build data from MES. This data not only tells ATS Inspect which unit is currently being inspected at each terminal but it also specifies which build options it has. This means that it can adjust the checklist questions for each vehicle. In return, ATS Inspect tells MES whether each unit can be shipped or not shipped.

Mobile Checklist

Over recent years this manufacturer has started to produce more vehicles abroad. This welcome new market proved to be problematic in that they required a lot more options on the vehicles.

This increased number of variables between each vehicle meant that there were more possibilities for mistakes to be made. Mistakes in vehicles being shipped abroad are far more costly as the correct parts need to be sent after them. Soon, costs of warranties forced immediate containment action.

To contain wrong options within the plant the customer can now walk around each vehicle, just before it’s shipped, and carry out a final check using a handheld device that displays the ATS Inspect checklist questions.

Reporting and Analysis

The reporting provided by ATS Inspect gives the company a powerful set of tools with which to view and analyse the quality data.

In many instances several people want to view the same report in different ways. ATS Inspect allows people to store sets of reports tailored to the requirements of their production area and tasks.

They can also generate reports automatically. For instance, an overview of all the defects found on a particular model of car in the last 24 hours can be generated and emailed to the line manager at the start of each day.

The Results

The customer has received countless benefits from implementing ATS Inspect but here are the key ones:

- Within a couple of months warranty claims for units shipped to the new market went down to zero.

- Protection against involving too many cars in case of a recall.

- Faster quality data analysis.