ATS Global implementa una soluzione Manufacturing Execution System (MES) in un impianto di confezionamento della carne per un’azienda internazionale di vendita al dettaglio

Obiettivo

- Achieve a paperless and fully automated production process

- Manage the receipt of incoming raw materials and inventory management

- Enable full product traceability and compliance as per regulatory standards

- To provide planning and scheduling of order

- Quality management

Scopo del Progetto

- Requirement identification and gap analysis

- Software architecture design and software functional design

- Solution implementation

- Integration with Advanced Planning and Scheduling (APS) and shop floor systems, testing and deployment

- 24/7 support

Soluzione adottata

- Agile software development

- Simulation of the shop-floor production lines

Competenza in sistemi, strumenti e servizi

- Siemens SIMATIC IT for Process Libraries

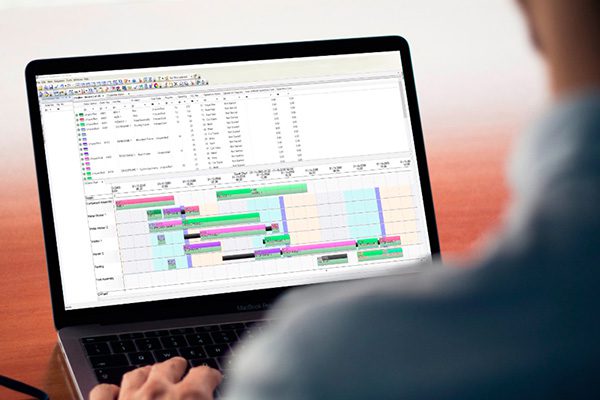

- Siemens SIMATIC IT Preactor

- Siemens Tecnomatix

- ATS MDM Library

- Rockwell (Allen Bradley) ControlLogix Data Concentrator

- 24/7 Support Services

Il risultato

Achievement of a paperless production process

Seamless planning and scheduling between APS and MES

Granular lot traceability

Complete inventory management of raw materials and finished goods