Digital Quality Solution for Weld Audits

Defects missed during weld audits are expensive to correct as components may be added after a frame or other substructure has been welded. Adding value to a defective structure simply means added costs to repairs or scrap.

As a supplier to an OEM, shipping non conformances on a welded subassembly means an expensive exercise in sorting, corrective action procedures and time. On top of all this, if you’re shipping in sequence to a customer, the time frame for identifying a weld issue and making repairs is short.

A digital quality solution can mitigate many of the problems that come with a paper-based inspection and help you to verify the critical quality aspects of your welds.

The Benefits of Going Paperless

Quality Alarms

With a digital quality solution, if a critical defect is found, or if a trend is emerging, an automated text or email notification can be sent to make the appropriate individuals aware of the situation. Alternatively, a message could be shown on an overhead display on the production line so that everyone in the production process is kept informed.

Getting the message to where it’s needed most in the fastest time possible is critical when you want to reduce the Cost of Poor Quality (COPQ). A faster response can reduce the number of defective units in your WIP and can aid in process improvement.

Ranking Non-Conformances

With a digital inspection you can have the power to automatically incorporate “ranking” of a weld number/defect combination. This means that a non-conformance can be specified as a “Failure”, or “Major”, or “Safety” or “Minor” based on the type of weld and the weld number/location based on your specifications.

This is just one example of the simple, yet essential, automation that can be introduced with a digital solution, allowing you to concentrate on acting on the analysis rather wasting time manually collating and re-entering data.

Empowering Data with Effective Analysis

With the results of weld audits being entered directly into a database, rather than being recorded on paper and then entered into a spreadsheet, real time reports are available, as well as reports generated on-demand based on aggregated data for all inspections.

These reports can highlight critical issues or important trends, such as which assemblies and sub-assemblies are high defect producers, which weld numbers are problematic and what your most common defects are. They can also identify high defect producing cells and robots so you can focus attention on the processes that have the highest Cost of Poor Quality.

One Size Can Fit All

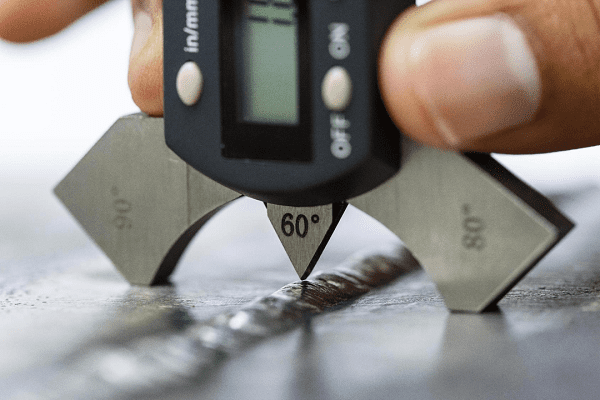

With a single digital inspection you can have a tool that will collate and standardise the data from all your standard weld inspections, including visual/non destruct/pry bar style audits typically performed on a high percentage of units produced.

And it can be used for any weld or weld related audits, such as adhesive audits, sealant audits, rivnut, rivstud or other joining technology.

If your weld analysis and reporting are not what they should be and your weld quality could use improvement, a digital inspection could be the tool you need to reduce scrap, rework and reduce your COPQ (Cost of Poor Quality).

Let’s discuss your data center requirements