High-mix manufacturing enables highly customized products to be created with the low unit costs associated to mass production. But how can you implement the flexibility required when producing built-to-order products while also maintaining the high quality standards expected by your customers?

The Product Quality Risks of High-Mix Manufacturing

High-mix manufacturing provides individually designed products to a mass market. This is now an established method with which manufacturers can set themselves apart from their competitors.

However, the manufacturing process requires flexibility, not only so that it can produce all of the custom requirements of each unit, but also so that it can implement the changes required for future products. This is because mass production is now entering the realms of trends, fashions, fads and even whims. With personalised products becoming more affordable people are becoming more bold and daring. They’re increasingly selecting options that suit their immediate desires but may only fleetingly be on-trend. This means that manufacturers need to update their offerings more frequently to stay relevant.

Quality control in mass production is a mammoth task at the best of times as even the simplest production lines will often be dealing with multiple variants of the same product. But what happens when you put everything up for grabs with hundreds of built-to-order options?

The one option that cannot be up for discussion is product quality. Built-to-order products can put a unique strain on existing quality assurance practices which often rely on regular processes and identical units. Quality control in high-mix manufacturing needs to be as flexible as the production processes. Thankfully, ATS Inspect is ready for this variability and the new working practices required by mass customization.

A Dynamic Inspection Process

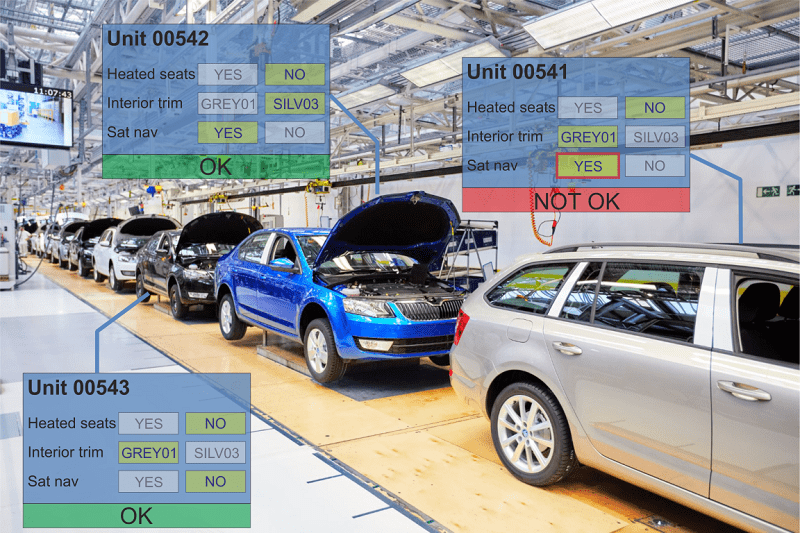

Production line operators around the world use ATS Inspect to perform visual inspections. When the operator identifies the unit they’re inspecting they’re presented with images or a CAD model of the product that corrolates to the exact build of the unit. The build specification is usually sent down directly from the PLM system. The operator can then record visual defects directly onto the images or CAD model.

Likewise, electronic checklists will dynamically adjust so that each unit has a personalised inspection. The operator will only see questions that relate to the current built-to-order unit. The correct answers will also update to match the current unit. This allows inspectors to safely confirm that all of the customizations have been correctly implemented.

With a direct link to the shop floor, ATS Inspect will even prevent units with quality issues from leaving the plant. With built-in logic it can either put the unit on hold until it’s fixed or re-routed to an offline rework station.

This individualized process means that no matter how the product has been put together, and even when every unit is different, no unit will ever leave the plant with an incorrect build or quality defects.

Built-in Traceability for Stress-Free Audits

You know what it’s like. An audit’s coming up and you’re not sure if you’ve got all your paperwork ready. Maybe it’s not even an audit. Maybe your boss simply wants to check that there haven’t been any transcription errors. Or maybe you’ve just been asked for a quality report of every vehicle with a particular component fitted. Whatever it is, this is where it’s best to part company with paper and spreadsheets. They’ve served you well up to now, but with the rising dynamism of high mix manufacturing, they can’t quite cut it.

With a digital quality solution such as ATS Inspect, you don’t need to worry about unexpected audits. Even random demands for information are a walk in the park. Your high-mix production may have become increasingly complex but your reports and quality analysis needn’t. And with every inspection recorded directly into the system alongside the location and the unit number, traceability comes as standard.

ATS Inspect allows you to keep track of your product quality in real-time from anywhere in the world through user-friendly, real-time, online reporting. In a few clicks you can review your overall quality levels or investigate specific variations.

You can even drill down into your quality data until you find the root cause of your issues. This can allow you to see if there are issues with specific variations or components. And then, with all the information you need at your fingertips, you can modify production processes to maintain product quality.

Giving the Customer What They Want

Customers will always want more variations of a product and mass customization is giving them the opportunity to have that. If we can choose the look and features of a product it gives us a deeper feeling of ownership. However, what customers will not accept is a drop in the quality they’ve come to expect from your brand. With ATS Inspect you can ensure that individuality does not come at the cost of quality.