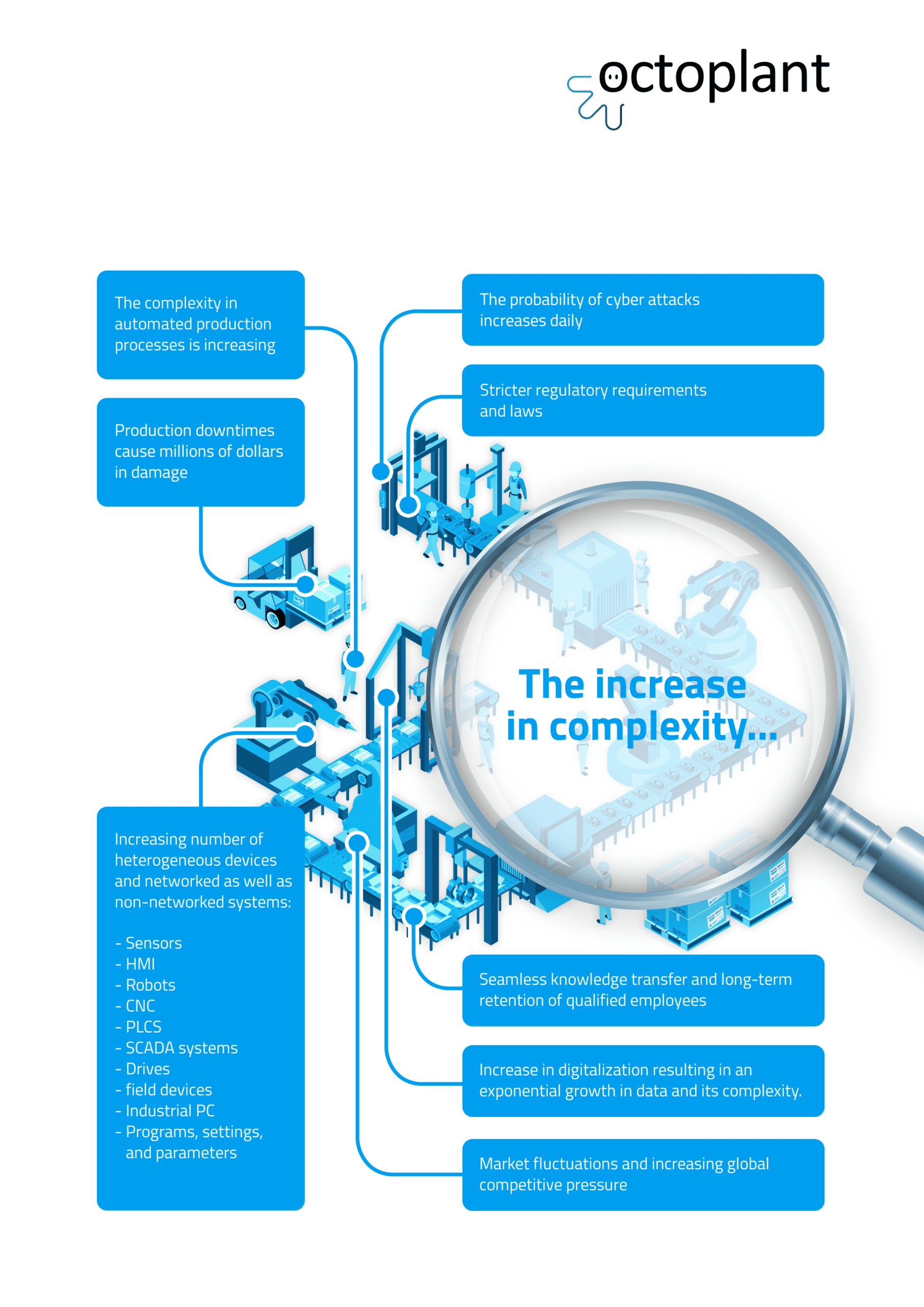

AUVESY-MDT provides complete solution for the Robust version Control & Data Management in automated environments.

Minimize downtime, reduce errors and increase safety in automated environments through better data management. Octoplant ensures data consistency and increased security in manufacturing facilities. The modular software platform offers comprehensive asset and device management as well as backups, adapted to the individual challenges of your industrial plant.

The next evolution in Data Driven Manufacturing

Achieve complete control over your production

environment and industrial automation

Greater data consistency, security, safety and reliability,

thanks to backups and version control

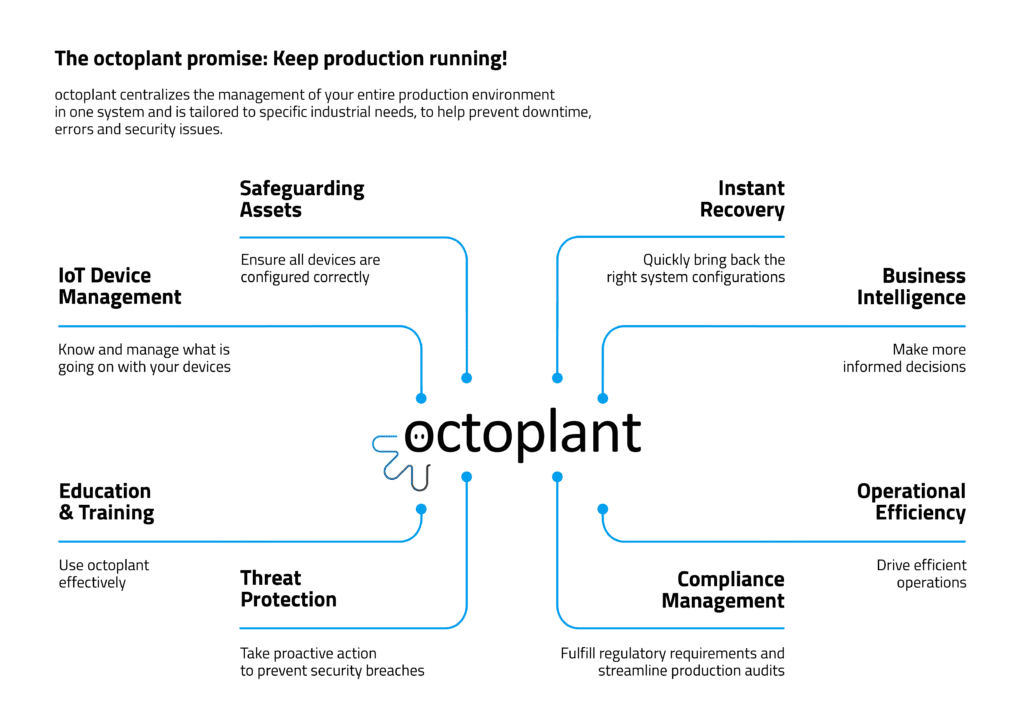

Octoplant centralizes the management of your entire production environment in one system and includes the following features:

1. IoT Device Management

Octoplant is vendor-independent and can connect to all commonly found automated production and IoT devices. As a central data management platform, it manages programs and configuration settings data in a standardized manner. By doing so, the solution ensures transparent management of complex information in a way that is both manufacturer-independent and solution-neutral across all common industry standards. It’s robust change history shows who changed what, where, when, and why, at a glance.

“Know and manage what is going on with your devices.”

2. Safeguarding Assets

By backing up assets, users can sleep soundly at night because octoplant helps safeguard automated production and ensures that the correct authorized version is always running. With complete version management, plant operators across the board always have access to the latest version and can see whether changes are required. The process of creating backups is automated – saving time and labor, reducing errors, and ensuring a reliable data snapshot of the entire production environment.

“Ensure all devices are configured correctly.”

3. Instant Recovery

octoplant’s capacity for instant recovery ensures that all necessary programs, data as well as the settings made within the scope of machine automation are available and are running correctly. It also allows for production to be restored at any time. In the event of an emergency, octoplant enables production environments and devices to be restored quickly as it eliminates the need to search for the last previously functioning version.

“Quickly bring back the right system configurations.”

4. Business Intelligence

octoplant consolidates the data of complex, fragmented production environments in one easy-to-use data management platform. It helps ensure that data is easy to analyze and thus guarantees better, safer, and faster decision making. Data can also be exported at any time.

This solution provides valuable insights, allowing the user to compare different production locations and devices, and helps aid reliable predictive maintenance.

“Make more informed decisions.”

5. Operational Efficiency

Octoplant enables companies to increase overall equipment effectiveness (OEE) by digitally connecting information from field, control, supervisory, and enterprise levels. octoplant adapts to existing workflows and (by comparing servers) provides information on how efficiently components are being used, and how frequently changes to specific components are being made. Guidelines and best practices for assets and configuration settings data can lead to an increased level of standardization and efficiency.

“Drive efficient operations.”

6. Compliance Management

Integrated documentation and regulatory workflows, such as those for the release process, help ensure reliable and seamless compliance management in which risks are reduced resulting in a rule-compliant, traceable, and auditable production process. Octoplant supports compliance with legal standards such as the KRITIS IT security law, the FDA 21 CFR Part 11 regulation, and GxP rules to ensure process quality, production documentation and proof of compliance.

“Fulfill regulatory requirements and streamline production audits.”

7. Threat Protection

Thanks to its proactive vulnerability, change, and risk detection features, octoplant’s holistic security architecture is able to protect production environments from attack, prevent damage, and avoid downtime. It breaks down the automatically assigned, regularly updated asset risk score for each inventory asset. Therefore, AUVESY- MDT’s solution can be used to prevent/reduce damage and shorten/ avoid downtimes thanks to its vulnerability, change, and risk detection features.

“Take proactive action to prevent security breaches.”

8. Education & Training

Finally, due to effective knowledge transfer, companies can help preserve their own production-specific knowledge and pass it on to new employees. The comprehensive e-learning platform enables employees to continue learning about octoplant anytime and anywhere. Best practices in the form of videos and webcasts can help improve job skills for everyone involved and ensure rapid onboarding when it comes to new equipment or production lines.

“Use octoplant effectively.”

Octoplant: